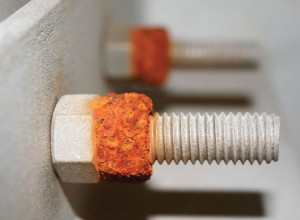

Fasteners are typically low cost items; however, their failures may result in catastrophic and costly consequences. A recent case of bolt failure that has received enormous media attention was associated with the San Francisco-Oakland Bay Bridge, the second busiest bridge in the nation. While investigations continue on the primary causes of bolt failures, corrosion was recognized as the foremost contributor. Corrosion is a naturally occurring phenomenon, the direct cost for which is a staggering $558 billion in the U.S. – approximately 3.1% of the U.S. GDP (2015).

Corrosion can be defined as the deterioration of materials (usually metals) by electrochemical interaction with their environment. Causes of corrosion initiation, rates of propagation, mechanisms of reaction and forms of corrosion products vary based on the type of materials, applications, and environmental exposures. Therefore, the risk of corrosion and preventive measures should be studied on a case by case basis. This article provides preliminary information on four common corrosion issues associated with ferrous mechanical fasteners (e.g., steel bolts and studs) and effective mitigation measures. Additional information and specifications can be sought through NACE International (The Worldwide Corrosion Authority) and ASM International (Materials Information Society). Top common forms of corrosion in threaded ferrous (steel based) fasteners are stress related corrosion (in the presence of cyclic or constant loading), hydrogen embrittlement, galvanic corrosion, and crevice corrosion.

Corrosion fatigue, in the presence of cyclic loading, and stress corrosion cracking (SCS), in the presence of constant stress, are known as the most common modes of failure for carbon and low alloy steel, as well as stainless steel alloys. Under tensile-stresses and exposure to corrosive environments (the presence of moisture and aggressive ions such as chloride), pits and cracks are formed within the microstructure of alloys reducing the expected yield strength. The higher the heat-treating temperature of the material (and the lower the ductility), the more susceptible it is to stress related corrosion. The first line of defense in controlling stress corrosion issues is to be aware of the issue in the design and construction stages. Controlling the environment, which may involve removal of aggressive ions, the use of inhibitors, or protective coating (e.g. polymeric coating), are possible methods of alleviating such corrosion problems.

Hydrogen embrittlement (HE) occurs due to the ingress of free hydrogen into a metal’s microstructure, reducing ductility and the load-bearing capacity of the metal. The sources of hydrogen are encountered in the manufacturing processes of steel (e.g., pickling), fabrication (e.g., coating and plating), as a by-product of other corrosion reactions, and improper use of cathodic protection for corrosion protection. The failure, typically, initiates at the points of greatest stress concentration (e.g., for bolts and screws at the fillet radius under the head). It has been shown that the parts with hardness of Rockwell C36 or below are less likely to fail from embrittlement. HE is recognized as a contributing factor to the SCS. The HE of fasteners has received significant attention in recent years, following high profile failure cases, while studies continue on identifying causes of failures. The best practice is quality control of fasteners prior to use in critical structures. Care should be exercised in specifying high-strength martensitic low alloy bolts in hydrogen rich environments.

Galvanic corrosion, a.k.a “bimetallic corrosion”, occurs when two dissimilar metals come in contact in the presence of an electrolyte (moisture containing salt). A galvanic cell is created and the most active (anode) of the two metals corrodes to protect the least active (cathode) metal. The best practice is to use similar fasteners as the joining metal. If not feasible, the surface area of the anode (least noble metal) should be greater than the cathode. It is a poor design practice to use carbon steel fasteners (least noble) in a stainless steel or copper assembly. Stainless steel fasteners (more noble metals) typically can be used in carbon steel assemblies, since the carbon steel will act as an anode. Application of non-conductive coatings on both metal surfaces has proven to reduce the severity of galvanic corrosion. Galvanic series tables are available as useful guides for compatibility of metals to be joined.

Crevice corrosion is a form of localized attack that most often occurs in narrow fissures where oxygen access is poor and a stagnant electrolyte solution is present. Crevice corrosion is insidious and can rapidly progress, resulting in the attack of metal within the crevice areas (e.g., beneath bolts and cracks already initiated due to stress related corrosion). Possible mitigation methods are: avoiding formation of a crevice, sealing crevices with caulking compounds or elastic joint seals and painting surrounding cathodic surfaces, inspecting regularly for signs of crevices, and applying cathodic protection.

While corrosion resistance of fastener materials is important, the entire assembled joint should be considered to prevent corrosion issues. A careful evaluation of structural design, working stresses, expected service life, type of exposure, metallurgical characteristics of fasteners, and joint assembly is required to prevent future corrosion issues.▪

References

1. CORROSION FAILURES: San Francisco Bay Bridge Bolt Failure, NACE International

2. Corrosion Costs and Preventive Strategies in the United States, a Study by FHWA/NACE International (2004)

3. NACE International, www.nace.org

4. ASM International, www.asminternational.org

5. Charlton R., Threaded Fasteners: Failure Modes and Design Criteria of Connections, NACE Corrosion 2011 (No. 1164)

6. Fundamentals of hydrogen embrittlement in steel fasteners, Brahimi S., IBECA Technologies Corp., 2014

7. Identifying Hydrogen Embrittlement Failure, Industrial Fasteners Institute