The Niagara River gorge had long separated the United States from Canada. It varied in depth up to 239 feet and in width generally between 800 and 1,000 feet between the Falls and Lewiston. Around 1836, suspension bridges were proposed by Francis Hall at Lewiston-Queenston and just above the falls. Charles B. Stuart, in 1845, then working on the location of the Great Western Railway in Canada, was looking for a way to connect his line with the Rochester and Niagara Falls branch of the New York Central. He proposed to span the gorge with a suspension bridge just above the Whirlpool. Many thought his idea foolhardy, as the only suspension bridges in the United States, other than some Finley bridges left over from the early part of the century, were Charles Ellet’s Fairmount Bridge over the Schuylkill River built in 1842 and John A. Roebling’s suspension aqueduct built across the Allegheny River in 1845. Stuart sent a circular letter to “a number of the leading Engineers of America and Europe, asking their opinion of the undertaking.” Of those who responded, only four thought the project feasible. Stuart wrote, “Charles Ellet, Jr., John A. Roebling, Samuel Keefer and Edward Serrell, alone favored the project…”

Ellet’s proposal was accepted, with modifications, for the sum of $190,000. The span would be 800 feet with a deck width of 28 feet. The deck would have two carriage ways, two footways and one railway track in the center of the floor. Ellet started by building a 9-foot wide temporary bridge but, after charging tolls for people to cross, he had a falling out with the Company in 1849. John A. Roebling took over the project in 1850, offering to build the bridge for $180,000 and to subscribe to $20,000 in stock in the bridge company. He changed his original design from a single deck structure to a double deck structure, with the railway on the top level and carriage and footways on the lower deck. Work would not commence on the Niagara project until 1852, with Roebling providing all engineering services including design as well as construction supervision. His company also supplied a significant amount of wire to be used in the bridge. He completed his 822-foot span double deck bridge in 1855. A one-track railroad ran on the upper deck (22 feet wide), and pedestrians and carriages passed on the lower deck (15 feet wide).

In 1874, T. C. Clarke, of Clark & Reeves Company and later Phoenix Bridge and Union Bridge Companies, was asked by the manager of the Western Railway of Canada to “report on the best mode of construction, necessary time required, and cost of a double track iron bridge.” He recommended, “a braced arch, hinged in the center and at the springing. The clear span was 430 feet, and the height or versed sine 175 feet. The arches were to have been erected by corbelling out as was done at St. Louis.” In 1882, the Michigan Central Railroad was ready to build its own bridge at a site near the suspension bridge. On October 13 they requested Charles Conrad (C. C.) Schneider to submit a proposal. They wanted “an estimate for a double-track railroad bridge of 900 feet clear span, for the purpose of ascertaining the probable cost of bridging the Niagara below the Falls, near the Railroad Suspension Bridge, intimating that a braced arch reaching from cliff to cliff might be the proper design for the proposed structure.”

Schneider had also been given the design for an iron bridge over the Fraser River, which flowed southerly into Puget Sound just north of the United States border. The Fraser River was a fast flowing stream which precluded the placement of falseworks in the river bed. Schneider, based upon his previous exposure to the Blackwell’s Island Bridge competition and Smith’s success at High Bridge, decided to build a bridge using a cantilever technique.

He completed the design of the 525-foot span, located 125 feet above the river, in the spring of 1882. The directors of the line decided to have the iron rolled and fabricated in England, a result of Prime Minister MacDonald’s tariff program that made United States iron and steel excessively priced. Canada had not as yet developed its own iron and steel industry to any significant degree. Due to the slowness of the delivery of the Fraser River Bridge iron (it reportedly took almost six months for the ship carrying the iron to Canada to make it across the Atlantic), it would not be completed until 1887 or four years after the Niagara Bridge. It lasted until 1910 when it was taken down and re-erected, one of the beauties of a pin-connected structure, across a chasm, appropriately called the Niagara Ravine, on a branch of the Canadian Pacific near Victoria, B. C.

Upon receiving more exact topographic information at Niagara, Schneider “decided that the cantilever plan would be most feasible and economical for this location…” He submitted his completed design to the Central Bridge Works of Buffalo, New York. They in turn submitted a tender to the Niagara Bridge Company that was accepted by the Board of Directors on April 11, 1883. Based upon better survey and boring information, he modified his pier locations which changed the span lengths of the cantilever. He also decided to use wrought iron primarily, with some steel.

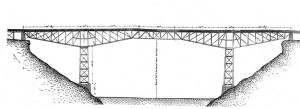

Schneider’s Plan for Niagara Bridge.

He chose to use Squire Whipple’s double intersection pattern (STRUCTURE magazine, May 2015), for his anchor and cantilever spans that George Morison, his mentor, used on his Missouri River Bridges and C. S. Smith used on his earlier cantilevers. On the short suspended span he, used a single intersection truss.

He wanted to have his piers of iron just as Smith had done at the High Bridge, but he decided to bring his iron work up parallel, in a direction perpendicular to the axis of the bridge. In order to make the structure determinant, he omitted the diagonals in panel BC; it is evident that no other strains can be transmitted between B and C than moments, the points of support being practically reduced to 2, and the shearing strain in panel BC becoming 0.

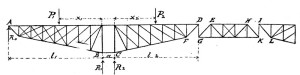

Layout of span and reactions, showing suspended span.

Schneider took great care in insuring that all the iron and steel, particularly the steel, met the specifications. In accordance with his experience “with steel for structural purposes which had to be made according to a specification, there have always been considerable delays, and this case was no exception to the rule. The records of the tests will show that the steel which has been accepted was of a good uniform quality.” With his design complete and quality of material acceptable, the fabrication of the structure took place in the yards of the Central Bridge Company.

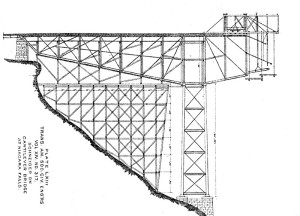

The erection technique worked out by Central Bridge Company and Schneider became the pattern that would be followed on many cantilevers in the future. They began by building the anchor spans from falsework resting on the rock banks and the towers by travelers off of the anchor span. The travelers worked outward on each cantilever arm until they reached the end of the cantilever span.

Traveler and erection sequence, showing falsework and traveler.

The suspended span was 120 feet long, and the maximum reach of each traveler was 40 feet. Schneider did not want the traveler to go beyond the end of the cantilever span, as he did not want to overload the span or the anchorage. This left 40 feet of suspended span which could not be erected by the travelers. He handled this by placing wooden beams across the 40-foot gap and erecting the rest of the truss by hand methods.

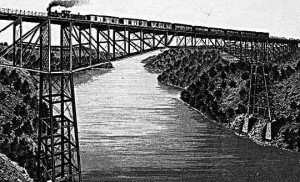

Niagara Cantilever.

The speed at which the bridge was erected was as impressive. Schneider wrote:

The first metal of the cantilever shore arm on the American side was placed on the falseworks on September 25th, and erection completed on October 15th. The erection of the cantilever shore arm on the Canadian side was commenced on October 8th, and finished on October 22nd. The traveler on the American side was completed on October 25th, and erection of the river arm commenced on October 28th. The traveler on the Canadian side was completed on October 31st, and erection of the river arm commenced on November 4th. The last connection was made on November 22nd, at 11:55 A. M.

The travelers and falsework were removed and the first track laid on December 6. The formal opening and testing took place on December 20, 1883. The bridge contained almost 4.5 million pounds of iron and steel, with about 70 percent of it being wrought iron. What Schneider and Central Bridge had done was to erect a new style bridge using new techniques, over 900 feet long and 230 feet over the Niagara River, in less than two months. The entire Niagara project, which started with foundation work on April 15, took only slightly more than eight months to complete. The bid price for the entire project was $680,000.

In 1900, or seventeen years after construction, the bridge was reinforced without material interruption of traffic by the addition of a new center truss midway between the original trusses and supported on a new tower trestle and anchorage pier on each bank. “The new superstructure has the same general outline and dimensions as the old one, and the details correspond so far as possible to those of the old members…It was decided to strengthen the bridge, not so much because it is unsafe under present loads but because the near future will evidently see trains and engines much heavier than are now being run across the bridge and heavier than was thought entirely safe for the original structure. The new truss is intended to be 50 percent stronger than either of the old trusses…In order to insure perfect safety against any uplifting of the anchorages, anchorage pits are being sunk about 25 feet under the end piers and the anchorage made there for the new truss in addition to the weight of the old pier…The material for the work is being furnished by the Detroit Bridge & Iron Works for plans made under my supervision [Benjamin Douglas, bridge engineer for the Michigan Central)…and the erecting is being done by the regular erecting gang. “

C. C. Schneider’s brainchild was reinforced without any apparent involvement by its creator. Schneider was still active in 1900 as Vice President in charge of Engineering for the newly formed American Bridge Company, located in New York City. The bridge was taken out of service and demolished in 1925 after having a useful life of over forty years. It was replaced by a steel arch bridge located between Schneider’s Bridge and Roebling’s Suspension Bridge (which was replaced with an arch by Leffert L. Buck in 1897).▪