The Pacific Rim, or The Ring of Fire, is commonly known as the area bordering the Pacific Ocean that attracts a high volume of seismic and volcanic activity from shifting plate tectonics. Over the past 100 years, 90 percent of earthquakes and 75 percent of volcanic eruptions have occurred in the Pac Rim, making it one of the most active and destructive areas in the world. With the recent influx of high-magnitude earthquakes over the past few years, we are reminded of the importance of seismic protection and its value in safeguarding some of our world’s most precious structural assets.

In creating a new structure during the design phase, it’s important to account for all possible causes of structural collapse. In order to adequately protect against seismic activity, energy dissipation devices such as fluid viscous dampers (FVDs) are often applied to mitigate structural sway in bridges and buildings. When properly specified and designed, fluid viscous dampers serve as a structure’s primary defense during a seismic event – preventing catastrophic damage and costly repairs.

Purpose and Practice

FVDs are often used as an energy dissipation device on structures built in seismic hotspots. A structure that utilizes fluid viscous dampers will increase its critical damping ratio and reduce the dynamic magnification factor. This reduction will reduce the dynamic response of a structural system in the event of an earthquake or other external excitation.

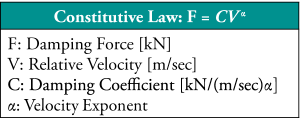

A fluid viscous damper is a device whose resultant force is proportional to its relative velocity (linear FVD) or some power of velocity (non-linear FVD). FVDs operate by converting kinetic energy into heat, typically over multiple cycles (tension and compression). This technology utilizes silicone fluid and custom orifice geometry to obtain linear (α = 1.0) and non-linear (α ≠ 1.0) fluid viscous damping performance. FVD performance is characterized by the Constitutive Law (Figure 1). Because of the inherent unpredictability of the magnitudes of earthquakes, engineers may want to consider a lower velocity exponent (α < 0.5). As the damping alpha decreases, the damping efficiency increases. For example, a FVD with an α = 1.0 has a damping efficiency of 78.5%, while a FVD with an α = 0.1 has a damping efficiency of 97.1%.

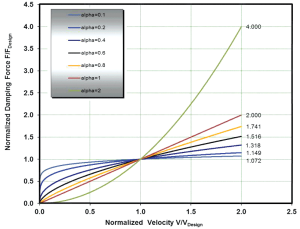

Most importantly, a low damping alpha provides more consistent damping force over a larger range of input velocities (Figure 2). For example, a FVD with α = 1.0 would be providing 2.000(X) the design damping force if the actual velocity input is 2.0(X) the design velocity. But, for a FVD with α = 0.1 if the actual velocity input is 2.0X the design velocity the FVD is still providing nearly the design damping force (actual 1.072X design force).

Application Use

When considering seismic support options for a building or bridge, it’s important to understand the advantages of using FVD devices over other types of energy dissipaters.

First and foremost, FVDs are applied to add damping to a structure, reducing structural response during periods of seismic excitation. From a lateral perspective, FVDs can reduce displacement and story drift, which lessens the stress placed on structural members. FVDs have the ability to reduce floor accelerations and, therefore, the inter-story shear and base shear/overturning moment.

In addition, FVDs are typically easy to install, operate and monitor in comparison to other devices. Design features such as internal fluid reservoirs and innovative sealing technologies extend damper design life. Monitoring options such as fluid indicators and cycle counting are part of a comprehensive health-assessment program that can help extend damper life and reduce risk of leaving a structure unprotected without the required damping in the case of a seismic event.

Finally, adding FVDs to a structure can often be a cost-effective solution for a long-term preventive maintenance plan. When considering the costs associated with structural damage, the initial purchase price is only a small portion of the damper’s total value, reducing the customer’s total installed costs.

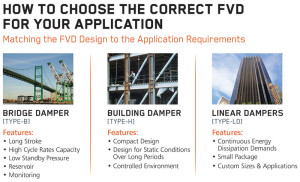

Figure 3. Customizing your FVD device to specific application requirements will extend the life of your entire structure.

How to Select the Proper FVD for Your Application

There are several areas to consider when selecting an FVD device for your unique application. To ensure proper installation and performance, design engineers must take the application requirements into account before choosing a device.

In some applications, specific requirements may warrant a combination of devices in order to achieve optimal protection. It’s important to remember that there is a wide array of technologies that are available for any application, and the goal is truly to find the most effective solution. For proper performance and desired response, specification of design features, testing requirements and documentation are all critical components during the design phase of a new structure.

For instance, a major manufacturer of seismic protection systems was recently asked to design a customized solution for a new oil rig structure. After analyzing the specifications, the team decided to use a tuned mass damping system with laminated rubber bearings and viscous dampers to help carry the static load, provide proper lateral stiffness and optimum critical damping ratio,. These combined technologies helped to improve the total system robustness, allowing for a more reliable structure and extended service life.

Extensive Testing Prior To Development Is Key

Because critical applications require high-performance devices, extensive testing is important for any damping technology being applied to a structure to ensure accuracy, repeatability and longevity.

As technology evolves, it is becoming imperative that structural engineers consult FVD manufacturers early and often to ensure achievement of the best available solution for any application.

What to look for when testing damping performance:

- Consistent and symmetrical damping force over multiple cycles

- No dead-band in performance between tension and compression cycles

- Test data that matches data for expected performance outcomes

- Data that matches application requirements

- Cycle outcomes that are repeatable and measurable

When designing a structure to withstand the impact of seismic energy, it’s important to consider utilizing additional support systems to provide adequate protection. Modern FVDs and other energy dissipation devices can extend the life of your structure, ensure safety for occupants, and foster a more reliable operation.▪