The value of constructable Building Information Modeling (BIM) to projects is evident, yet it remains a common misconception that structural engineers get the least benefit from it. But, as many structural engineering firms can attest, it doesn’t have to be that way. Instead of following the lead of architects who suggest or require the use of BIM, structural engineers should assume the lead by building “constructable” models that can be used downstream by all subcontractors throughout the life of the project. This seems straightforward, yet many structural engineers are still wondering, “what’s in it for me?” To answer that question, it is first important to understand constructable models and how they have the potential to be an added revenue source for the structural engineer, while at the same time providing the owner with a streamlined process that should reduce overall costs.

What is Constructable BIM?

All 3D models are not BIM and also are not necessarily constructable. For example, models that contain only visual 3D data but no object attributes, or those that allow changes to dimensions in one view but do not automatically reflect those changes in other views, are not BIM. These types of models are useful for architects to communicate a building concept and vision to the owner and subcontractors, but they lack the data to support construction, fabrication and procurement, and thus are not constructable models. In reality, this is typically the way structural engineers work, taking an architect’s model, adding the structural elements and then supplementing the 3D model with a set of 2D drawings, usually created from a homemade library of standard details for things such as steel connections and concrete reinforcement. And to be fair, there is nothing fundamentally wrong with the structural engineer’s end product from this process; a full set of 2D construction documents is produced and conveys the design intent. This is usually what a structural engineer is requested to do and is often referred to as Level of Development (LOD) 300 in the contract.

However, this approach can be very inefficient for the structural engineer; there are two potential problems. Change management is time consuming and, as the 2D drawings are not always a product of the 3D model, the structural engineer is required to do twice as much work for the same result. Secondly, the 3D model is not useful downstream to others in the process because it does not contain enough detail or information and often is not accessible, meaning constructability and clash detection cannot be checked.

Constructable models can provide an added revenue source for structural engineers along with a streamlined process that should reduce overall costs for the owner.

An Opportunity for Structural Engineers

Expecting a structural engineer to spend time creating a model that contains all the information requested for fabrication and construction is not realistic. It is also unreasonable for a structural engineer to spend additional time creating a model solely for the benefit of someone else, unless fees are incurred for the additional work. However, if the owner was prepared to spend a little more money at this phase of the project, the overall savings of the construction phase as a result of reductions in change orders and RFIs could be significant. This is the advantage of a constructable model.

So why should a structural engineer be interested in creating a constructable model? You could argue that structural engineers should want to create buildings that fit together purely for professional pride, but pride alone doesn’t pay the bills. Arguably, structural engineers are perhaps in the best position to harness BIM for their own advantage as well as the benefit of the entire project, from design to fabrication to construction. Constructable models can provide an added revenue source for the structural engineer, while at the same time providing the owner with a streamlined process that should reduce overall costs.

Constructable Models Offer a Wide Range of Benefits

Improving Communication & Collaboration

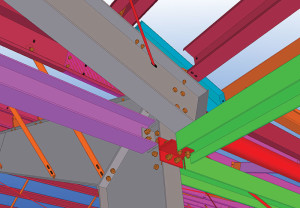

Constructable BIM breaks down communication barriers between project stakeholders. It provides a source of detailed unified information that becomes a trusted repository of collective accurate data and measurements to ensure consistency as each trade builds their own models. Because everyone works on models that share common source data, the models can be overlaid to detect clashes before materials are ordered or construction begins.

In this way, constructable models foster frequent communication between architects, design engineers and trades because they are the product of collaboration. This open and frequent communication produces the opportunity for better and more efficiently built structures completed within even the most demanding schedules. The entire project team benefits from speedier, clearer communication and improved coordination. Fabricators and erectors, in particular, will benefit from better planning and management tools, and greater understanding through visualization.

Estimate and Material Accuracy

Creating a detailed, information-rich structural model allows structural engineers to extract accurate material quantities to produce more competitive bids with much lower contingencies. In addition to giving structural engineering firms a competitive edge for winning business, constructable models enable materials to be sequenced and ordered with confidence to reduce waste and the cost of fixing mistakes discovered at the jobsite.

French structural engineering firm Sarl Patrick Millet was tasked with extensively remodeling and expanding the 60-year-old skating rink in the Alpine town of Gap, France. Because of the accuracy of the constructable model detail, such as the dimensions and quantities of the steel required for the project and the ability to generate accurate drawings from the model, Millet issued its fabrication orders with confidence. Despite the project’s geometric complexity, there were no fabrication errors.

Estimating for atypical jobs such as remodels and expansion projects can also be achieved with constructable models. In these cases, the model is created using a combination of source data such as 3D laser scans of the existing structure, drawings and as-built information. This process creates an accurate project scope and produces accurate material quantities.

Clash Detection

RFIs delay projects. When progress stops because a problem is discovered or someone needs more information, the project schedule suffers a setback. Using constructable models brings clarity to RFIs and leads to quicker resolution because they allow structural engineers to communicate and resolve issues with trades through the model. A model-based RFI can include a text description of the problem along with a screen capture, enabling the involved parties to immediately understand the issue and its impact. The model can be marked up and passed back-and-forth in real time, much like an attachment can be attached to an instant message.

National construction services company Barton Malow is taking the practice of using constructable models to resolve RFIs and reduce change orders a step further for the remodel and expansion of the Daytona International Speedway grandstand, which is scheduled for completion in 2016. The company requires all of the trades to post open standard Industry Foundation Classes (IFC) files of their updated models to Dropbox each week.

The McGill Engineering office in Tampa, Florida, downloads the updated models from the other trades into their structural steel model, and uses a clash detection function in their BIM software to discover problem spots. When a clash is found, the other trade’s model is imported into McGill’s working structural steel model and the problem is fixed. If it can’t be fixed in the steel model, McGill takes a snapshot of the clash and sends it along with an RFI to the appropriate trade for redesign.

Structural engineering and building firm Gregory P. Luth & Associates, Inc. in Santa Clara, California, started using constructable building information models in 2006. Constructable BIM has allowed them to resolve conflicts and congestion during the design phase, which streamlines construction. Even when change orders are issued for design changes, making those changes to a constructable model reduces latency. Instead of taking weeks, the firm can have rebar in the field within seven days of receiving the change order because they can generate revised shop drawings direct from the updated model for the fabricator. This practice allows jobs to proceed much more efficiently, with no second-guessing.

Reducing Waste

Building and sharing constructable models reduces waste throughout a project, from time wasted during the design phase to material waste, which translates to time and cost savings. Over the last 10 years, Walter P Moore has developed a spectrum of constructable models, ranging from Advance Bill of Material (ABM) model to a fully-connected detailed model. To further leverage model sharing, the firm wrote custom API interoperability tools for several design and analysis, and documentation platforms. These translators allow their structural engineers and steel detailers to quickly and automatically build models in their BIM software from models created in other platforms by other trades. Not only do these translators save project time, but they allow the firm’s engineers to spend more time designing; not remodeling.

Reducing Risk & Liability

Perhaps one of the most frequent arguments against building constructable models and sharing them is the perception that this practice increases risk and liability. This likely comes from the counsel of overly cautious attorneys and insurance agents during the early days of computer-aided design and 3D modeling technology. The truth is actually the opposite, according to structural engineering firms that routinely do this. In fact, it can actually reduce liability insurance premiums by reducing a firm’s claims, one of the factors in determining premium costs.

A large percentage of claims stem from miscommunication, a problem that is greatly improved when design engineers produce constructable models in collaboration with others on the project team such as architects, steel detailers and steel fabricators. Sharing constructable models reduces risk for structural engineers because it gives everybody access to the same information at the same level of detail and allows them to comment within the model, thereby enhancing communication.

Structural engineering firms that routinely build and share constructable models add tremendous value to projects.

What’s Stopping Structural Engineers?

The reality is that, in many cases, structural engineers are simply using the wrong BIM software. There are a number of options available and choosing the right one isn’t always easy. In an ideal world, the structural engineers should be able to use a BIM solution which:

- Has been designed specifically for structural engineers, not architects.

- Enables the creation of a 3D model intelligent enough to generate all of the 2D drawings.

- Enables the 3D model to be created more quickly than creating the 2D drawings manually.

- Integrates seamlessly with the structural engineers chosen analysis design software.

- Would be accurate enough to pass downstream to be used by the detailer for detailing purposes (LOD 400).

- Provides the structural engineer with the option to include more detail than LOD 300 if required (with very little additional modeling time required).

Structural engineering firms that routinely build and share constructable models add tremendous value to projects through better designs, enhanced collaboration, better cost management, less waste and jobsite efficiencies that go right to bottom line. And, this tool leads to delighted owners, more repeat business and referrals, lower risk and even reduced liability insurance premiums.▪

All graphics courtesy of Nucor Buildings Group.