Given the choice, and the apparent difficulties of the alternative, this may seem like superficial advice for navigating a daily routine. This bit of counsel, however, has impacts far beyond mere cognizant awareness of the surrounding environment. Most have heard or been given the guidance, “keep your head on a swivel” – often in relation to sports, or perhaps even before entering precarious situations, but these recommendations may not be expected among the cubicle warriors of engineering firms. Taking time to look around may just save a project schedule and budget in a matter of minutes.

Rarely is it more important for an engineer to be omniscient than on a site visit. Never mind the direct task at hand – walking down systems, updating project staff, identifying progress, or ensuring quality – staying out of harm’s way is a full-time (not to mention the most important) responsibility. Too often in an efficiency-driven industry this awareness is lost in the “I’m here to do this … or I need to look at that …” mentality, and engineers lose sight of the bigger picture: the whole project’s goals.

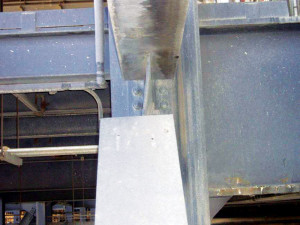

A recent site visit to investigate the failure of slide plates on a flue gas ductwork system reinforced this concept as well as any class, design concept, or code document ever has. As a structural engineer, my eyes are continually drawn to the steel and concrete infrastructure that dominates the power industry in which I work. On the trudging climb to the top of a precipitator structure to walk down the subject ductwork, an oddity in the braced frame structure jumped out. To the chagrin of many architect counterparts, this structure was intended to be concentric, aligned, straight, square, the whole bit – but it was no longer. One of the large first-tier vertical braces had shifted noticeably out of plumb (Figure 1). After further investigation, I discovered that the gusset and web splice connection plates had buckled, further causing the web of the wide flange brace to begin tearing down the axis of the member (Figure 2).

The piece of the story that has yet to be told regards the large new ductwork support structure that was in mid-design back at the office, soon to be built adjacent to the precipitator. It would be counting on this existing structure for both lateral and vertical support in varying capacities. As is typical in retrofits, the client had provided a set of existing structural drawings, the contract was written such that the new design could reasonably rely upon the owner-provided documents, and consequently the small proverbial snowball of design began rolling, formed around the nucleic assumption that the structure would look and act as the drawings indicated. Though it was later determined that the existing structure had likely relieved its excess load through the displacement of the brace, thus finding a new path to its foundation, and was stable in its current condition, it most certainly would not have been sufficient for the new loads that were going to be introduced.

Luckily, that snowball had not yet reached terminal velocity – about which a structural engineer knows nothing, but it sounds great in print – on its way down the hill of the project schedule toward construction, and thus the design could be redirected to stand on its own without the help of the failed bracing system. Though a more expensive approach, it was certainly the prudent one given the developments, and it would provide the client with the expected reliability and safety.

So why tell this little story? Investigation of the existing ductwork slide plate was a separate scope of work, under a separate agreement, largely unrelated to the major air quality control system design/construction project taking place at this site; but the impact of that climb up the stairs became far-reaching. Probable schedule and budget impacts were averted due to the early detection of the existing conditions, not to mention the potential for a catastrophic failure in the future. There were certainly no “atta boys” or accolades provided for the find, nor should there have been. This was not a personal victory, but one for the project and the long-term interest of the owner – after all, it is the fundamental obligation of all engineers to protect the safety, health and welfare of the public and their clients (in that order) – it is just doing the job. It is a reminder that – with all the metaphorical blinders of contract language, performance pressure, future repeat business, and economy of design – there is no relief from the overarching duty of due diligence in project work. That includes simply paying attention to the “that looks odd” moments.

Though it is likely feasible to scratch out a few pages of calculations while staring at the back of closed eyelids, this certainly does not stand as a challenge to try. Instead, think of it as a reminder that an engineer’s responsibility on a project goes far beyond the tasks at hand, and entails always – ALWAYS – keeping those eyes open. Clients depend on it.▪

Structural Forum is intended to stimulate thoughtful dialogue and debate among structural engineers and other participants in the design and construction process. Any opinions expressed in Structural Forum are those of the author(s) and do not necessarily reflect the views of NCSEA, CASE, SEI, C3Ink, or the STRUCTURE® magazine Editorial Board.