Designers dedicated to restoring ecosystems and enhancing social conditions through the built environment know that wood can contribute significantly to this aspiration. Although timber used as structural elements in taller buildings is not a new concept, it has been largely abandoned as a solution in favor of other materials. Projects around the world are demonstrating the potential of engineered, mass timber products as structural elements for tall buildings, and wood is re-emerging as a viable and beneficial option.

Learning from the experiences of early adopters in the industry is essential for building capacity, credibility and market acceptance for tall wood buildings. In the fall of 2013, the Survey of International Tall Wood Buildings (the Survey) was conducted with the goal of collecting lessons and experiences from built projects. The aim is to share this information with potential North American project stakeholders to help simplify processes, increase comfort, and potentially lower the risk of designing tall wood structures, ultimately broadening the uptake of wood systems used in tall construction.

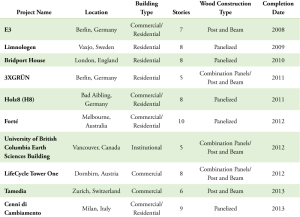

The Survey included ten completed projects around the world (see Table), and focused on gathering lessons and experiences from four stakeholder groups: Owners/Developers, Design Teams, Construction Teams and Authorities Having Jurisdiction (AHJ). The Survey methodology included a short, online questionnaire followed by a more in-depth, in-person or telephone interview. Researchers also conducted site visits for nine of the ten surveyed projects. This work offered a unique opportunity not only to learn from specific project experiences, but to cross reference results, aggregate information, and identify trends.

The work focused on discovering the rationale for pursuing structural wood solutions and lessons about design processes, construction processes, approvals, and unique aspects associated with delivering a tall wood project. What follows are a few highlights of the results describing the range of design solutions applied across the surveyed projects, followed by best practices for navigating approvals.

Design Solutions

All panel systems are generally favored for residential construction, while a combination of post and beam and floor panels is favored for institutional and commercial space – likely because post/beam offers a more open floor plan that can be reconfigured easily. Panels provide a more compartmentalized layout, well suited for residential. Where a combination of structural systems and materials were applied (concrete, steel, glass, mass timber), complexity and the overlapping of trades impacted the schedule. Designers indicated that detailing interfaces between materials was exceptionally time consuming, owing in part to the variation in tolerances between materials. Simplified solutions and approaches were pursued to mitigate this effort.

Among the projects surveyed, lateral stability is achieved through either a concrete core or Cross Laminated Timber load bearing walls, some reinforced with steel tie-down rods. The Earth Sciences Building with exposed, ductile heavy timber chevron bracing, is the only exception. Connection solutions are unique in almost all project examples, although solutions appear to be evolving and focusing quickly.

3XGRÜN. Architecture by Atelier PK, Roedig Schop Architekten and Rozynski Sturm. Courtesy of Stefan Mueller.

Early projects struggled with complex steel connections between wood elements as well as wood-concrete connections. More recent buildings focused on simplifying design details to better support modular prefabrication, assembly, and building configuration. Pure timber connection strategies also vary and appear to be evolving quickly. Each surveyed project has a unique solution to avoid compression perpendicular to grain at horizontal joints; however, self-tapping, angled screws appear to be emerging as an economical and reliable strategy to secure joints, along with steel plates as a tie down method.

Team members for projects that used concrete cores all emphasized that use of precast concrete panels accelerates the construction schedule and maintains a dry site. Of the projects that used cast-in-place concrete for the core, almost all of the schedule savings afforded by other prefabricated components were lost due to long curing time.

Envelope: Moisture Protection and Durability

Generally, design teams did not perceive moisture as a major risk. In all cases, any exposed structural wood elements were either inside the building envelope, protected by an overhang or, in the case of cantilevered panels, exposed only on the underside. In two cases, moisture sensors were installed to monitor envelope performance as part of ongoing operational research projects.

Fire Protection

Fire protection strategies varied depending on authority requirements, and a range of solutions were implemented across participant projects. In all cases, fire testing was conducted in collaboration with research institutions or other industry partnerships.

Strategies included oversizing timber elements (where required) to include a char layer, in addition to encapsulating timber with gypsum to some degree. Sprinkler systems and intumescent paint applied to exposed timber were also common fire protection strategies, although not consistently required or applied across projects. Most projects chose not to install wood cladding on the exterior, and opted for non-combustible façades; where wood façades are used, fire protection strategies were more challenging and complex. Generally, designers indicated that solid timber products supported good fire protection given that open spaces in wall assemblies were limited or eliminated.

Best Practices for Navigating Approvals

Navigating the approvals process is identified as one of the most significant challenges with advancing mass timber systems for tall buildings. Of the projects included in the Survey, none of the local jurisdictions explicitly recognized mass timber systems in building codes, and all facilitated some form of ‘Alternate Solutions’ process. Every participant project experienced a different approvals process based on existing codes, degree of market acceptance for mass timber as material for taller buildings, and varying regulatory policy, but they all emphasized the importance of collaborating with authorities early to establish methods of compliance and methods of testing.

Of the ten participant projects, only one approval pathway was already established (3XGRÜN), owing to the E3 project completed a few years earlier in the same jurisdiction. All other projects were the first to overcome code barriers and challenges successfully. Participants identified three important strategies:

- Start educating the authority when you start educating yourself. Share information, expertise and engage local authorities by inviting them into the discourse, providing them with credible industry resources, and engaging them in research.

- Establish an acceptable method of compliance as early as possible with the AHJ, to allow the team to plan for testing and account for extra time associated with creating a new path to approvals.

- Plan for on-site inspections by the authority during construction. The Survey results confirm that where authorities were able to visually inspect assemblies and observe construction process and quality, their level of comfort increased and sense of risk decreased. In some cases, authorities deemed multiple fire protection strategies redundant and allowed a revised, less onerous approach.

Conclusions

The Survey results highlight that a range of design and construction techniques can be successful, and that they are still evolving to respond to the varied code requirements, market demands and expectations, climates and regulatory conditions, and lessons learned from earlier projects. To build more momentum and support for built examples in North America and around the world, a clear lesson from the Survey is that a deeply integrated and collaborative process between all design disciplines, fabricators, research institutions and regulatory bodies is essential. The breadth of design considerations necessitates a greater blending of professional roles across teams working on tall wood buildings; for instance, structural engineers must be concerned with acoustics, vibration, fire, and aesthetic performance of exposed structural building elements, where these issues are not typically integral to design considerations of more established structural systems. Working closely with other design disciplines, fabricators, researchers, and authorities at all project stages will be essential to advancing successful examples of tall buildings with solid timber structural elements.

Forestry Innovation Investment (FII) and the Binational Softwood Lumber Council (BSLC) engaged Perkins+Will, with Equilibrium Consulting Inc., to conduct the Survey. For more details and to access the Summary Report for the Survey of International Tall Wood Buildings, please visit www.rethinkwood.com/tall-wood-survey.▪

Disclaimer: The Summary Report was developed by a third party and is not funded by reThink Wood or the Softwood Lumber Board.