Structural Engineering Challenges

Who would have thought that designing a 10-foot (3 meter) by 13-foot (4 meter) structure would present so many unique challenges? The structure, a single family shelter, seemed very straightforward at first; however, a field visit to Leyte Island in the Philippines proved otherwise. The task was to develop structural drawings for a shelter unit that is being provided to the most vulnerable victims of super typhoon Haiyan. Nearly 1,080 units are to be built by July 2015. This article presents some of the challenges encountered, including anticipation of load conditions, availability of materials, and quality of materials received.

On November 8, 2013, super typhoon Haiyan hit the Philippines, devastating the Visayan Islands in Central Philippines, particularly the islands of Samar and Leyte. The super typhoon, locally known as Yolanda, had winds exceeding 190 mph (300 km/hr), making it equivalent to a hurricane Category 5 on the Saffir–Simpson hurricane wind scale. The strong winds and rain brought flash floods, landslides and immense destruction. This mega storm killed more than 6,200 people, damaged 1.1 million homes, and left some 4.1 million people displaced (USAID, 2014).

Several non-governmental organizations (NGOs) mobilized personnel to help restore the community. Medair, a Swiss based NGO, rapidly responded to the humanitarian crisis by reaching out to remote and rural communities that had not received assistance. Medair found almost total devastation in the Dulag municipality, 19 miles (30 km) south of Tacloban. The typhoon had damaged or destroyed 9,004 houses (81% of all homes); leaving approximately 44,000 people, out of a population of 53,883, displaced from their homes (Medair, 2013). Medair’s shelter construction project is now underway.

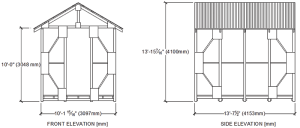

After an assessment of the needs and the living habits of the local population, architects from Medair rapidly developed a prototype shelter. Figure 1 shows elevation views of the structure in its first phase. Initially, the unit is enclosed by means of a tarp, allowing for immediate occupation and future expansion. This initial phase provides 129 square feet (12 square meters) of living area; however, the owners could increase its size to 301 square feet (28 square meters) as their income allows. This can be accomplished by adding two rooms, one on each side of the house.

Once the main concept was developed, the structural design started. Fundamental principles of design for high-seismic and high-wind loads were followed. Many aspects of the design and construction had unique challenges. These are discussed next with the intention of helping the readers understand challenges encountered when designing relief structures in undeveloped regions.

Anticipation of Load Conditions

Several complications arose when determining the design loads for the shelters. First, the National Structural Code of the Philippines: NSCP Volume 1 (ASEP, 2002), was used to determine the design wind loads. These were compared to ASCE 7 (ASCE, 2010) and results were very similar. The unique challenge here was to obtain the NSCP and to learn how to implement it.

Once the design was nearly completed, a visit to similar relief shelters built in the region revealed two new issues that had not been considered. First, because of potential flood exposure in many locations, the floors were not on the ground as initially thought; instead they were attached to columns. What was really worrying was the fact that, given the approximate 13-foot clear height of the roof ridge, and the floors often being placed at around mid-height of the columns, a two-story house was basically created. This produced a significant deviation from the original design, increasing the load on the columns. Secondly, with regard to seismic loads, what was initially thought to be a lightweight structure with insignificant mass, coming mostly from roof dead loads, now became a structure with a mass at the elevated floor location as well.

Another unique aspect of the loading conditions was created by the enclosure used for exterior walls. The initial phase included the distribution of a tarp to be placed around the shelter to provide protection against wind and rain. Accordingly, the lateral-force resisting system was designed to withstand the forces generated by the wind pressures acting on the membrane. Several houses visited, however, had not used the provided membrane and were instead using a locally produced thin fabric called Amakan. This fabric is made by weaving bamboo strips at 90 degree angles (Figure 2). These fabrics have large gaps between the bamboo strips, which allow for wind to flow through the shelter. This membrane is also very likely to let water enter the shelter even during moderate winds. Under high wind pressures, the Amakan fabric will possibly fail, allowing wind to flow through the shelter, reducing wind pressure on the main lateral-force resisting system but increasing the pressure at roofing elements. The solution, if all the scenarios are to be considered, is to design the lateral-force resisting system for the maximum loads coming from the full wind pressure, when the structure is enclosed, while the roof should be designed to withstand uplift from an open structure.

Availability of Materials

Coco lumber is a natural resource widely available in the Philippines. It is extensively used for housing construction in rural areas because of its availability and relative low cost. An extensive amount of coco trees fell during super typhoon Haiyan, increasing the supply of this inexpensive material. Figure 3 shows a typical coco lumber supplier found by the side of a major road in Tacloban. However, coco lumber requires careful processing and strict quality control for it to serve as structural lumber. Untreated coco lumber exposed to weather is very susceptible to fungi and termites, which can destroy the hard portion of the trunk in less than 2-3 years and the soft portion in just a few months (Arancon, 2009). Although treatment would increase its life span, treated coco lumber was not readily available in the region. Furthermore, available coco lumber from local supplies varied greatly in dimensions and density. Much of it was cut using chainsaws, resulting in uneven pieces of lumber. Given the uncertainty of the quality of the coco lumber found, it was not used for structural elements. However, in order to promote the local economy, coco lumber was specified for non-structural elements that will not be directly exposed to the weather. It is important to aid the local economy as much as possible without compromising the structural integrity of the shelters.

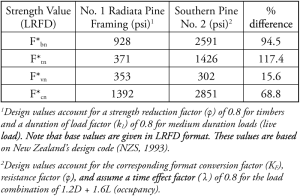

The construction managers consulted several suppliers in the region and decided to import treated No. 1 Grade Radiata Pine framing from New Zealand. This wood species is not included in the National Design Specification® (NDS®) for Wood Construction (AWC, 2012), normally used for design of wood structures in the United States. Thus, the New Zealand timber construction standard, NZS 3603 (1993) had to be consulted to find the design strength of these species. Upon inspection, it was found that the strength value given does not include the same adjustment factors as the US design specification. Thus, these strength values could not be applied directly in the NDS member strength equations. Instead, strength values were adjusted according to New Zealand’s design standard.

It would be erroneous to assume the properties of the lumber used, based on a typical grade of species group normally found in the USA. As an illustration, the Table compares the adjusted strength values, ignoring stability, for No. 1 Radiata Pine framing with those of No. 2 Southern Pine for a 2×4 section. Note how the difference can exceed 100%. Although this point may seem obvious, verifying other designers’ calculations for overseas shelters, on two different occasions, revealed the use of design properties from a typical USA species group/grade even though the wood used was a local wood with significantly different properties.

Quality of Materials Received

Another challenge was to obtain materials with the requested quality. Often the material received was substandard. One example is the requested marine plywood, which ended up being regular interior plywood whose product name was marine plywood. Another example is the wire used to tie purlins to rafters, which corroded in a short time after installation because the galvanization was inadequate. To complicate things further, nails provided did not follow the same dimensions as those in the United States, but they were instead a little shorter. For example, a 16D common wire nail in the US has a 3½ inch length. In the Philippines, nails provided were often only 3 inches long. This was solved by specifying the required length and diameter of the nails.

Conclusion

The intentions of this article are to share the experience encountered when designing a transitional shelter in an undeveloped region of the Philippines, and to raise awareness for future relief projects. It is crucial for a design team to research and anticipate many of these challenges before finalizing the design phase, in order to better serve these communities. An early site visit is necessary since it can potentially reveal any challenges and possible solutions to those challenges. This relief effort is currently underway with 1,080 units to be built by July 2015. The aspects discussed in this article were taken into account, and included in the construction plans and documentation currently used by the construction crews. This project is a great example of how the structural engineering profession can help under-served communities.▪

References

Arancon, J. (2009). The situation and prospects for the utilization of coconut wood in Asia and the Pacific. Asia-Pacific Forestry Sector Outlook Study, Working Paper No. APFSOS II/WP/2009/15. Food and Agriculture Organization of the United Nations, Bangkok, Thailand.

ASCE (2010). Minimum Design Loads for Buildings and other Structures, ASCE/SEI 7-10, American Society of Civil Engineers, Reston, Virginia.

AWC (2012). National Design Specification (NDS) for Wood Construction with Commentary 2012 Edition. American Wood Council, 222 Catoctin Circle, SE, Suite 201, Leesburg, VA 20175.

Medair (2013). The Philippines: Caught in the Path of a “Super” Typhoon. Fact Sheet, retrieved from http://relief.medair.org/en/where-we-help/emergency-response-typhoon-haiyan/

NZS3603:1993 (1993). Timber Structures Standard. Standards New Zealand 6th Floor, Wellington Trade Centre, 181-187 Victoria Street, Wellington 6001.

USAID (2014). Philippines – Typhoon Yolanda/Haiyan. Fact Sheet #22. April 21, 2014, retrieved from www.usaid.gov/what-we-do/working-crises-and-conflict/responding-times-crisis/where-we-work

Association of Structural Engineers of the Philippines (2002). National Structural Code of the Philippines (NSCP 2001), Vol. 1 – Buildings, Towers and Other Vertical Structures, 5th ed.