The Forum in Inglewood, California (also known as the Fabulous Forum) is an arena with a cable-suspended structure – not unlike a suspension bridge. There are 40 columns positioned equally on a 404-foot diameter circle that taper into precast concrete arches which support the 70-foot high compression ring. Forty cables, each 3 inches in diameter, one from each column, are strung from these columns to a central tension ring. The entire roof structure sits on the cables. The inward force (pull) from the cables is countered by the giant compression ring, which, at the time it was designed, was the largest compression ring in America. In its original design, one hundred percent of the heavy lifting is done by the cables (Figure 1).

Designed and built in the early 1960s, the Forum’s structural design favored economy of construction with little concern of future expansion. But music acts today are bringing in heavier and heavier gear – video boards, lighting, LED arrays, speaker banks, rigging – and they want to suspend it all from the roof/ceiling rather than build their own structures. The Forum’s roof cables simply did not have enough reserve capacity to support these shows. To further complicate the design, the rigging consultants recommended the addition of a tension grid system to cover almost a third of the cable area under the roof. In a tension grid system, individually framed panels with tensioned wires create a walking surface where riggers can easily walk and drop motorized cables and chains from the primary structure above to support the lights and sounds below. This would further increase the demand on the existing roof structure.

One Ring to Push Them

The typical demands for increased loading capacity when you retrofit a building are on the order of 20 or perhaps even 50 percent – but the Forum’s owners wanted to increase the load capacity of the roof by around 300 percent. The capacity needed could not be obtained with conventional reinforcement design techniques. A completely out of the box, innovative solution was needed. Inspiration was found in the giant cathedrals of ancient Europe. They are all domed structures, which always have a compression ring at the top in the form of an oculus. They also have a tension ring around the perimeter to resist the dome’s natural tendency to flatten out. In a dome, all forces radiate outwards.

At the Forum, the roles are reversed. The compression ring is on the perimeter, and the tension ring is at the center, at a slightly lower elevation. Contrary to a domed structure, in this arena all forces move in a direction opposite to a domed structure. This is not a compression structure, but a pure tension structure. The ring outside is being pulled inwards because the sag of the cables causes all forces to radiate inward.

The engineering logic was to create a modern-day version of a dome and marry a new compression structure to the existing tension structure (Figure 2). It would relieve the forces on the existing exterior perimeter ring, and generate the extra capacity. A hybrid structure like this had never been designed before – this would be the only structure of its type in the world that had both a tension ring and a compression ring at its center.

Data Collection

Accurate design requires precise knowledge of the existing structure. As the cables act in a non-linear manner, simple structural analysis methods do not generate accurate results. Possessing the original structural drawings without having the sequencing of the cable erection and jacking, and the original pre-tensioning magnitude, was insufficient to accurately model the structure. As the original sequencing and jacking forces of the cable structure were not available, further investigation was necessary. Knowledge of the exact cable location in its current state, and an inventory of the existing loads supported by the cable along with the precise amount of force currently in the cable was required to accurately model the structure in absence of the original sequencing. Measuring the cable locations in space was easily achieved with a 3D laser scan of the ceiling. This provided information on the location coordinates of all cables for the entire roof. Finding the existing force in the cable was more complicated, requiring a ‘lift off’ test of the cable. The ends of the existing cables were concrete encased at the completion of installation. During the ‘lift off’ test, the concrete encasement was chipped away, exposing the end wedge fitting of the existing cable. A jack with a custom threaded and fabricated pin was used to engage the cable end. The cable end was then slowly pulled until the end cap of the cable wedge lifted off the compression ring, thereby transferring the entire load from the cable into the calibrated jack (Figure 3). At that one instantaneous moment in time when the cable moves, the point of equilibrium shifts and the existing cable force is determined. This procedure was repeated multiple times. Once all data was collected, it was then input into Severud’s own custom created software, where the output quickly converged, giving the final results.

One Ring to Gather Them

Severud’s design concept envisioned that a new structure would be created within the volume of the existing roof and be seamlessly merged with the existing structure in the same curved roof plane, taking advantage of the subtle curve of the roof (used for drainage). A compression ring was then introduced, like an oculus in a cathedral, except it was fashioned out of steel to bring the entire compression structure together. The new structure, in combination with the existing structure, does all the heaving lifting. The cables continue to support the roof as well as take up any unbalanced rigging loads.

Getting the new compression ring into position required careful planning. No mobile crane could just lift this ring up above the perimeter of the roof, reach more than 240 feet from the edge of the promenade at the perimeter of the arena to the center, and then gently lower this massive ring. Severud elected to design the new Compression Ring such that it could be raised up to the roof from the arena floor. That meant that the new compression ring had to slide up through the center opening of the existing Tension Ring to its final top-chord position. That dictated the 19-foot diameter of the ring. Compression forces dictated the 2.5-inch plate thickness (Figure 4). False-work was erected, a hydraulic lift was placed, and the new ring was raised into position. The new domed structural framing was then loosely connected to the new Compression Ring and the entire system was allowed to gently settle so that the forces could re-distribute themselves (Figure 5).

Figure 5. Steel compression ring being lifted into place at top. Steel tension ring is in view at the bottom.

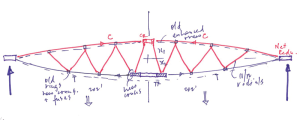

One Ring to Tie the Two and Bind Them

Once the new structure settled into equilibrium and all elevations were recorded, the jacks went to work again and raised the new system a precisely calculated amount. The goal was to balance the compression forces from the new structure racing towards the outer perimeter ring with the tension forces from the existing structure racing away from the outer perimeter ring so that the perimeter ring became the binding element. The old tension system was integrated with the new compression system utilizing twenty radial trusses, resulting in a structure dubbed by many of the concert riggers as the ‘best rig on the west coast.’

Rock Concerts, Performance Events, Seismic Events and Asymmetric Loadings

The Forum sits approximately four miles from a seismic fault line. It is in a zone of high seismic activity. It is also a perfectly symmetric structural design. The ideal seismic design is one where the center of mass is coincident with the center of resistance, resulting in a perfect balance of forces during a high seismic event. However, the majority of the concert and performance events are not “In the Round” (centered in the arena) but are “End Stage” events resulting in an asymmetric loading on the structure. The effect is negligible during a routine event but when hanging 300,000+ pounds asymmetrically, it poses a further challenge. The designers had to make sure throughout the building’s renovation that the building’s center of mass stayed the same, and that the total mass did not increase beyond a set percentage. If an element was added or removed, it had to be balanced out with a similar operation on the other side. It was also necessary to compensate for the addition and removal of loads that were strictly event-dependent. Structural Engineers value redundancy. But performance artistes never conform (that is why they are artists!). The design of the Forum required the study of every possible concert configuration from past concerts and, working with the rigging consultant, potential future concerts. The arena was then re-structured to absorb all of these possible scenarios.

Proof of the structure’s performance capability came in August 2014 when the MTV Video Music Awards Event was staged in the arena (Figure 6). A total of 300,000 pounds of equipment, speaker banks, video walls, graphics boards, LED banks, moving catwalks, etc. was hung from this innovative structural system. 300,000 pounds, hanging about 65 feet off center, on a 404-foot clear span caused this tension-compression structure to deflect a total of 17/8-inch. A very good day in the office.

The authors would like to thank Manny Morden, P.E., S.E. for his invaluable efforts on this project.▪

Project Team

Owner:

The Madison Square Garden Company

Consultants:

Severud Associates: Structural Engineer of Record

Brisbin Brook Beynon Architects: Architect of Record

ME Engineers: MEP Engineer of Record

Clark Construction Company: General Contractor

Gafcon: CM/Owner’s Representative

Ed Kish Rigging: Rigging Consultant

Beck Steel: Steel Fabricator

Bragg Steel: Steel Erector

IA Stage (Skydeck): Tension Grid Fabricator