Hot-dip galvanizing provides a cathodic, barrier, and zinc patina protection of structural steel from corrosion. Structural steel put through the hot-dip galvanizing process goes through a series of chemical cleaning steps leading up to the final step of being completely immersed in an 830° F bath of molten zinc. The heat effect on the steel, the viscosity properties of the cleaning solutions and zinc, and the resultant metallic zinc coating, requires certain design parameters be met to ensure the steel after galvanizing performs precisely as the engineer intends it to.

The Process

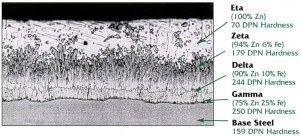

Batch, or after-fabrication hot-dip galvanizing is a factory-controlled process whereby mild or high-strength steel is progressively cleaned in caustic, acid (hydrochloric or sulfuric) and flux solutions prior to immediate immersion in a bath of 830° F, molten zinc. In the molten zinc, a coating on the steel develops as a result of a metallurgical reaction. The coating consists of four layers, three of which are zinc-iron alloy, and the fourth is a top layer of pure zinc. As a result of this reaction, a tightly adherent, abrasion resistant coating is formed. In fact, the three zinc-iron alloy layers are all harder than the steel itself and have a bond to the steel of approximately 3600 psi, making for a tough coating, difficult to damage during erection and exposure to harsh wear and tear. Typical coatings on structural steel will be in excess of 4 mils, but can vary based on the thickness and type of steel. Unlike most coatings where a thickness is specified, the galvanizer must provide a minimum coating thicknesses depending on which coating specification is used.

How Zinc Protects Steel

The zinc coating is metallic in nature and thus impervious to moisture. It serves as a barrier and isolates the substrate steel it is protecting from any electrolyte solutions (water, dew, rain, salt water), one of the requirements for electrochemical corrosion of steel. Zinc is anodic to steel, i.e. zinc exposed to air will sacrificially corrode before any of the substrate steel it is protecting will rust. This includes when scratches and gouges occur during the erection phase. The surrounding zinc corrodes first before any steel corrosion takes place. The corrosion rate of zinc in most atmospheres is very low, meaning the hot-dip galvanized coating will cathodically protect the steel underneath from corrosion for 75 years, and often more. In the zinc corrosion process, the zinc coating progressively forms a patina of zinc oxide, zinc hydroxide, and finally zinc carbonate. The carbonate film is tightly bound to the zinc underneath, very passive, i.e. slow to react with corrosive elements in the air, and is not water soluble.

Galvanizing Implications for Design

Approximately 3.4 million tons of structural and miscellaneous steel is hot-dip galvanized each year in North America. Certain characteristics of the process and resultant zinc coating require some well-thought out planning and consideration by structural engineers. (See Hot-dip Galvanizing for Corrosion Protection – A Specifiers Guide, 2006, American Galvanizers Association or Design Guide – The Design of Products to be Hot-Dip Galvanized after Fabrication, 2012, American Galvanizers Association, for more information)

Viscosity

Steel designs must provide venting and drainage outlets on the parts to be hot-dip galvanized. In the cleaning process of steel to be hot-dip galvanized, the fluids can penetrate between overlapped steel surfaces unless they are seal-welded. Because the viscosity of molten zinc is low compared to the cleaning solutions, it does not penetrate into the overlap areas. The temperature of the molten zinc is 830° F and creates a virtual high pressure enclosure in the overlapped areas, one which can explode, destroy the fabrication, and cause serious injury to the galvanizing personnel in the plant.

Vent/Drain Holes

When immersing welded round, square, and rectangular hollow structural sections (HSS) with closed ends in molten zinc, there must be holes somewhere near both ends to allow air to escape out the top and molten zinc to enter in the bottom. Otherwise, the air pressure doesn’t allow the zinc to flow throughout the inside of the piece, and consequently no zinc coating forms on the inside where most corrosion begins.

Keyhole method of draining zinc from a pole during removal from the molten zinc of the hot-dip galvanizing process.

Welds

All welded areas must be clean and free of slag prior to arriving at the galvanizer’s plant. The cleaning solutions do not remove the slag and the result is uncoated steel.

Coating Thickness and Bolted Connections

Tapped through-holes must be re-tapped oversize after galvanizing when used in conjunction with galvanized bolts, because the bolt shaft is slightly larger in diameter due to the addition of zinc coating to the bolt threads. Oversizing holes according to American Institute of Steel Construction (AISC) guidelines is usually sufficient to account for the zinc coating’s thickness.

Bolts are completely galvanized, but internal threads in holes or nuts must be tapped oversize after galvanizing to accommodate the increased diameter of the bolts. And, although the re-tapping or chasing cause a bare steel condition on the female thread, the zinc on the bolt threads protects both components from corrosion.

When galvanized bolts are used in conjunction with galvanized and faying structural members, the surface must be roughened or coated with a zinc-silicate paint to achieve a 0.5 coefficient of friction. Exact procedures for this roughening are currently being developed by the American Galvanizers Association. No special preparation of galvanized surfaces is required for bearing connections.

Mechanical Properties

According to studies by the BNF Metals Technology Centre in the UK (as well as numerous other national and international studies), hot-dip galvanizing produces no significant changes in the mechanical properties of the structural steels or welds commonly used throughout the world. The galvanized substrate is chemically and metallurgically equivalent to the uncoated steel.

Embrittlement

Structural steel severely cold-worked (punched, notched, sheared, or bent sharply) is susceptible to strain-age embrittlement. This embrittlement is relatively slow to occur in ambient temperatures, but may be immediately evident after exposure to the elevated temperature of the galvanizing bath. Precautions such as selecting steel with carbon content less than 0.25%, bending with a radii of at least 3X the section thickness, and more are detailed in ASTM A143, Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure for Detecting Embrittlement.

When galvanized steels of ultimate tensile strength of 150 ksi (1050MPa) are used in design, grit-blasting instead of acid-pickling should be specified. The steel can then be flash-pickle cleaned for just a few minutes instead of 45 to 60 minutes. This minimizes the introduction of gaseous hydrogen which becomes trapped in the grain boundaries during the pickling process. Too much hydrogen in high-strength steels causes a change from ductile to brittle steel, aka hydrogen embrittlement of the steel.

Distortion

Some fabricated assemblies, and even asymmetric shapes such as channels, may distort at galvanizing temperature as a result of relieving stressed induced during the steel production and/or fabrication operations. Keys to minimizing distortion include using symmetric rolled sections, parts of equal or similar thickness (so the heating/cooling gradient in the 830° F zinc bath is nearly the same), and large bend radii. For a complete list of tips refer to ASTM A384, Safeguarding against Warpage and Distortion During Hot-Dip Galvanizing of Steel Assemblies.

Special designs can minimize distortion when fabrications comprised of dissimilar thickness are required.

Appearance

Galvanizers make regular process modifications to improve coating thickness consistency and appearance, all the while adhering to the requirements of the ASTM specifications. Overshadowing those improvements is the fact that the steel chemistry is the overwhelming determinant of both coating thickness and aesthetics. Besides iron in steel, which reacts with zinc to form the coating, there are trace elements of silicon (Si) and phosphorous (P). Steels containing Si and P outside recommended ranges are known as reactive steel, and may produce a coating of almost entirely zinc-iron alloy layers. Such coatings tend to be thicker than normal, infrequently making edge areas susceptible to flaking when impacted by tie-down chains during transport or when jarred by contact with other steel during loading/unloading and erection, and tend to be matte gray in appearance.

Reactive steels are still galvanized on a regular basis, and it is important to note differences in appearance have no effect on the corrosion protection afforded by the galvanized coating.

Specifications

The predominant hot-dip galvanizing specification in North America is ASTM A123, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products and covers coating thickness requirements for various steel section thickness, sampling, and inspection procedures. ASTM A153, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware, is the complementary specification for bolts, nuts, and other connection types.

Within these standards is the understanding that certain design details are required and it is critical there is an open line of communication between the structural engineer, fabricator, and galvanizer. This communication loop helps eliminate costly pitfalls and helps ensure everyone’s expectations are met.

Sustainability

Zinc and steel are 100% recyclable. Approximately 95% of all structural steel is produced from recycled steel and 30% of all zinc produced comes from recycled sources. The rate for zinc would be much higher if material would be available. The fact is most galvanized steel is in use for 70 years or more. More importantly, the reclamation rate for zinc is 80%, i.e. of all zinc available for recycling, 80% is recycled.

Zinc is a naturally occurring metal, the 27th most prevalent in the earth’s crust. It is used in myriad consumer products from vitamin supplements and cold remedies to sunscreens, baby ointments, tires, and coins. Zinc is required for all organisms to live and reproduce. But, by far the largest use of zinc is to protect metal from corrosion via its application in the hot-dip galvanizing process.

Sustainability measurement is rapidly progressing to encompass the complete stream for any product from raw material to final use. For hot-dip galvanized steel this means measuring the energy consumed and emissions generated from the mining of zinc and steel, smelting, and application on steel to the recycling phase and back to raw material. The emphasis of the galvanizing industry is that no maintenance of galvanized steel is necessary for 70 years or more. This means the environmental impact is almost exclusively confined to the production phase. This is unlike most other coatings, which require periodic and frequent maintenance throughout their service life.

The only environmental impact during the use-phase results when the zinc coating corrodes over many decades and makes its way back into water and soil from which it was mined. When the zinc coating is exposed to air and goes through the natural wet and dry cycles of weather events (rain, snow, fog), it oxidizes and very slowly, often 75 years or more, makes its way into streams, rivers, oceans, and lakes. These compounds (zinc oxide, zinc hydroxide, zinc carbonate) are added to the existing background level of zinc in the water, but only on a very temporary basis. The zinc level does not accumulate in water due to the interactions between zinc and the various water quality constituents present in natural waters. The suspended solids in water (minerals and coarse organic material) decrease the total zinc due to settling and are incorporated into the sediment. Over time, the system maintains a consistent ambient zinc concentration in the water column and sediment because there is a constant supply of new sources of suspended solids in the flowing water. These new sources remove and bury the zinc in a continuous cycle. Even if there are multiple sources of zinc, the dilution factor and suspended solids removal is such that the natural background level of zinc is relatively unchanged approximately 2500 feet downstream from each zinc source, and even closer for bodies of water with very large volumes such as oceans.

This addition of zinc to the water environment does not cause the background level of zinc to exceed the criterion level, defined by the U.S. Federal Clean Water Act, as the amount of zinc in water causing toxicity to aquatic organisms.

Summary

The hot-dip galvanizing process is unique in that it economically protects valuable structural steel from corrosion, but it requires some special design considerations in order to deliver the precise requirements specified by the structural engineer. When the structural engineer understands the governing specifications for hot-dip galvanizing and is in constructive communication with the architect, fabricator, and galvanizer, all expectations are met. And, the use of galvanized steel assures that sustainability has been integrated into the final project.▪