Why it Almost Mattered

At the time of this writing, a vacant former bakery is standing for a few more days at the corner of Fifth Street North and Seventh Avenue North, just outside of the official boundary of the local and national historic Warehouse District of Minneapolis, Minnesota. The building is typical of others in the area: a one- to three-story utilitarian structure with little architectural ornamentation and several additions. The hodgepodge of construction styles is reflected by the variety of structural systems found within, including load-bearing masonry walls, cast iron columns, and framing of heavy timber, structural steel and reinforced concrete; the building is a dictionary of historic construction techniques. It is a familiar scene in many urban industrial areas: declining industries leave behind a decaying infrastructure and abandoned buildings. For years this bakery has stood with boarded windows, roof leaks, squatters, and active plundering of any metals of value. However, a recent urban revitalization has brought redevelopment interest to many of the buildings nearby.

The Warehouse District is notable for its representation of the growth of industry in Minneapolis, which was supported by the early arrival of the railroads. The initial construction in the area was from the mid-19th century to support the local milling industry – first lumber, and then flour. By 1902, the connection of major railroad lines brought industries such as wholesaling and manufacturing; Minneapolis eventually became the center of distribution for America’s farm machinery. Growth in the District reached its peak around 1930, and then declined along with the rest of the American economy. Concurrently, several changes in interstate shipping legislation allowed for independence from the railroads that had been so critical to the growth of the economy in Minneapolis. The District remained relatively unchanged between 1930 and 1990, which left many of the original historic structures intact, albeit untended.

A recent survey of the area identified buildings that are potentially historic. A low-rise structure without any prominent architectural features, a series of mismatched additions, and a leaking roof might typically be dismissed. However, a 1909 building permit card for the bakery noted that the “fireproof Kahn concrete tile system” was used in the building’s early construction. Furthermore, the bakery is purportedly the site of the invention of “sliced bread” and other innovations in the baking industry. Thus, when a proposal for a new apartment building suggested demolition of the bakery, the Minneapolis Heritage Preservation Commission was charged with making the decision as to whether to allow it: could the use of the Kahn system be significant enough to merit saving it? Furthermore, how important is “sliced bread” anyway? An engineering condition assessment was ordered to determine the structural integrity of the building, and the importance of sliced bread was left to the opinion of the Commission.

The “Kahn System” was invented by Julius Kahn, who filed a patent for it on December 11, 1902. Julius was the brother of the more well-known Albert Kahn, a nationally prominent architect based in Detroit who is best known for the factories he designed for automotive companies such as Packard and Ford in the early 20th century. Albert incorporated his brother’s patented reinforcement into many of the buildings he designed. Meanwhile, Julius formed the Trussed Concrete Steel Company, also based in Detroit, to manufacture, market, and provide structural engineering services for his proprietary system. It serves as the structure for buildings throughout the country, such as the Engineering Building (1904) at the University of Michigan and the Blenheim Hotel (1906) in Atlantic City, New Jersey.

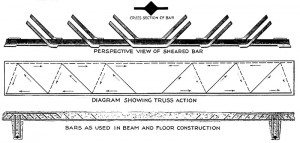

Figure 1: Illustration of cross-sectional and perspective views of the Kahn reinforcement bar, along with a diagram of the theoretical “truss action”.

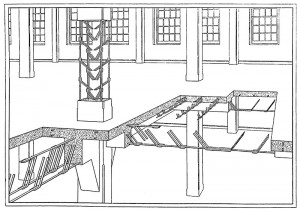

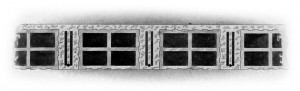

At that time, reinforced concrete was inherently experimental as engineers and builders worked to understand how to design and construct safe and efficient structures from the material. Numerous patented systems were developed, such as Ernest Ransome’s twisted steel reinforcement and Claude (C.A.P.) Turner’s “mushroom system” of flat-slab floor construction using smooth round rods. Kahn’s reinforcement system was unique: it consisted of visually distinctive rolled diamond-shaped bars with flat-plate flanges (or “wings”) that were sliced and bent up at regular intervals at approximately 45 degrees from the longitudinal axis of the reinforcement. Kahn rationalized that concrete members constructed with his reinforcement, particularly beams, would act in bending as a Pratt or Warren truss, with the diagonal wings and longitudinal bars serving as tension members and the concrete serving as vertical (or diagonal) compression members (Figure 1). The diagonal wings were also theorized as shear reinforcement. The system was incorporated into reinforced concrete beams, joists and – in early examples – columns (Figure 2). Joists were typically installed with a hollow clay tile block system that consisted of rows of blocks laid with a three- to four-inch space between. Kahn-style reinforcement was placed into the voids between the blocks, which were subsequently filled with concrete (Figure 3). The hollow clay tile blocks were left in place, which resulted in a smooth underside suitable for finishing with plaster. The bakery used the hollow clay tile joist construction method for the floor in the 1909 addition.

A publication by the Trussed Concrete Steel Company claimed that the system offered 20-30% greater capacity compared to “beams reinforced with horizontal rods and loose stirrups with the same area of reinforcement.” These claims were based on tests performed in 1907 at the University of Wisconsin on simply supported beams. According to the test report provided in the Trussed Concrete Steel Company publication, the beams with “loose stirrups” failed due to slippage of the rods and concrete shear near the supports. In contrast, the Kahn-reinforced beams were claimed to fail in flexure near the center (Figure 4). A review today of the test data shows that the test beams with “loose stirrups” were constructed with smooth longitudinal bars and U-shaped shear reinforcement spaced at intervals of at least three-quarters of the depth of the longitudinal reinforcement. While the lack of testing standards and documentation from that time leaves some questions today about the validity of the tests, the intention of the testing was clear: to demonstrate the strength of the product, to create confidence in the product for contractors and building code officials, and to promote a proprietary reinforcing method.

Kahn’s reinforcing system drew both attention and criticism from contemporary practitioners. In particular, C.A.P. Turner, a nationally prominent engineer based in Minneapolis, vehemently objected to Kahn’s system in his 1909 book, Concrete-Steel Construction:

In theory the Kahn bar is supposed to act with the concrete after the manner of a Warren Truss, and proof of this theory as advanced by the advocates of this type of reinforcement, reminds one of the story of the friendly discussion between two lawyers, in which the question came up as to who was recognized as the most prominent attorney in the place.

“I am of course,” said the first. “How can you prove it?” asked his friend. “Why, I do not need to prove it, I am willing to admit it,” replied the first.

Thus the advocate of this type of reinforcement apparently advances similarly convincing proof that the bar acts in the manner claimed.

Turner also pointed out that because of how the bar was manufactured, the “wings” at the ends of the bars were shorter. He noted that shear stresses were greatest at the ends of a simply supported beam, where the Kahn System provided the least amount of shear reinforcement. Turner further critiqued it for not providing continuous longitudinal reinforcement for the beams at the columns, which created a potentially catastrophic and brittle failure mechanism; in contrast, Turner and several other engineers at the time promoted a configuration of continuous longitudinal reinforcing over the top of the columns. Another shortcoming was that as the length of the “wings” increased, the spacing of the “wings” also increased, which effectively imposed an upper limit on the shear strength of a beam of fixed depth.

The Kahn System was involved in at least two catastrophic building failures. In November 1906, the Bixby Hotel in Long Beach, California partially collapsed during construction. Engineers investigating the collapse of the hotel concluded that premature removal of formwork and shoring was the cause. Two weeks later, the Eastman Kodak Building in Rochester, New York collapsed during construction. Investigators found numerous flaws in the quality of the work. They found a large amount of wood debris and sawdust in the concrete, as well as improperly placed reinforcement in many locations. Both investigations concluded that the collapses were not due to faulty design or flaws in the Kahn-style reinforcement; rather, they were the result of poor workmanship.

Ultimately, increasing standardization of concrete reinforcement systems and greater understanding of reinforced concrete behavior led to the decline of numerous proprietary methods of reinforcement, including the Kahn System. Reports published by the Joint Committee on Standard Specifications for Concrete and Reinforced Concrete in 1908, 1912, 1916 and 1924 provided specifications and guidelines for the design and construction of nonproprietary reinforced concrete structures. As concrete reinforcement became standardized into the form most commonly used today, the Trussed Concrete Steel Company broadened its market into products such as concrete pan joist formwork and steel window frames, and shortened its name to the Truscon Steel Company in the 1920s. In 1935, it became a subsidiary of the Republic Steel Corporation. The company no longer exists today.

The pending demolition of the bakery presented many questions about both the structural and historic integrity of the building. From a structural perspective, the consulting engineering company (Minneapolis-based Meyer Borgman Johnson) was required to determine whether the building, and especially the Kahn System, was adequate to support current and proposed floor loads. A partial collapse in the area of the Kahn reinforcement, coupled with the known inadequacies of the reinforcing and significant corrosion after years of water intrusion, led to the conclusion that the floor system likely lacked sufficient strength to support any code-mandated loads in its current condition. Repair of the system was deemed cost-prohibitive and invasive.

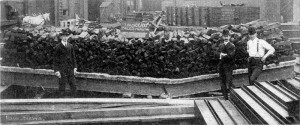

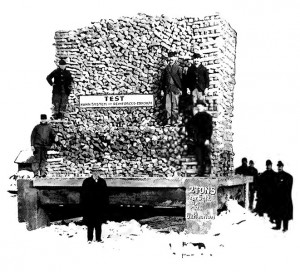

The historic integrity and significance of the system is less clear than an engineering comparison of demand versus capacity: did the bakery building, and specifically the Kahn reinforcing, represent an important part of construction history in the Twin Cities of St. Paul and Minneapolis? There are a few other remaining buildings in the area that incorporated the Kahn System. The “Northwest” branch office of the Trussed Concrete Steel Company designed the structure for the Minnesota State Fair Grandstand, as well as the Lowry Building in St. Paul. A description of the Kahn System in Cement Age, a trade journal of the time, mentioned that the nine-story, 450,000-square-foot Farwell, Ozmum, Kirk & Co. warehouse in St. Paul was built in 1906 with a reinforced concrete structure using the Kahn System throughout. The warehouse was designed to carry 500 psf, and was load-tested after construction to 1,500 psf by piling pig iron eight feet high in a floor bay. It currently serves as the East Building of the Ramsey County Government Center. The Nichols, Dean, and Gregg Company Warehouse in St. Paul was constructed in 1906, and was claimed to be the “strongest in the world” by the architect and contractor. Although the veracity of this claim is unknown, it was certainly a strong building as proven by load testing (Figure 5). Other buildings may have used the system, but documentation of the reinforcement type is not available.

Figure 5: Test panel constructed with the Kahn System loaded to 4,000 psf with iron ingots for the Nichols, Dean and Gregg Warehouse Building in St. Paul, Minnesota (demolished 1990).

Kahn’s type of reinforcement is one of dozens of novel patented systems available at the beginning of the 20th century. The Kahn system exemplifies the intensive innovation, entrepreneurship, and experimentation seen in reinforced concrete construction during this period. Perhaps it is not coincidental that the inventive engineers commonly named their proprietary systems after themselves, and actively marketed their technology through testing programs, technical treatises, and paid advertising. Many of these systems have been lost to demolition, neglect, or simple lack of documentation. As engineers and historians, we ask what role engineering and construction history should play in the field of historic preservation. What lessons can we learn from these systems and this period of time? How did these engineers and their inventions influence concrete construction today?

The demolition of the building was ultimately approved. The Kahn system, and the original home of sliced bread, will no longer be in Minneapolis.▪

All graphics from the Kahn System of Reinforced Concrete or Kahn System Standards publications.

References

John J. Flather, “Concrete Failures,” Concrete Engineering 1 (February 15, 1907): 95-96.

Donald Friedman, Historical Building Construction (New York: W.W. Norton & Co., 2010), 148-155.

Julius Kahn, US Patent 736,602, filed December 11, 1902 and issued August 18, 1903.

John W. Leonard, Who’s Who in Engineering: 1922-23, (New York: John W. Leonard Corporation, 1922), 1102.

“Lowertown’s Historic Nicols, Dean and Gregg Building Demolished,” Preservation Matters 6 no. 1 (January 1990): 1-2.

Minneapolis Department of Community Planning and Economic Development, “Minneapolis Warehouse Historic District Design Guidelines,” (March 2, 2010).

Minneapolis Department of Community Planning and Economic Development, “Staff Report: Demolition of a Historic Resource,” August 21, 2012.

Water Mueller, “Reinforced Concrete Construction,” Cement Age 3 (October, 1906):313-332.

“Partial Collapse of the Bixby Hotel at Long Beach,” Western Architect and Engineer 7 (1906): 45-49.

Ernest Ransome, U.S. Patent 305,226, filed May 1, 1884 and issued September 16, 1884.

William Ganson Rose, Cleveland: The Making of a City (Ohio: Kent State University Press, 1950): 882.

Trussed Concrete Steel Company, Kahn System of Reinforced Concrete (Detroit: Author, 1904). http://archive.org/details/kahnsystemofrein00trus

Trussed Concrete Steel Company, Kahn System Standards (Detroit: Author, 1913): 5-12. http://archive.org/details/cu31924015414695

Trussed Concrete Steel Company, “Report of Tests on Reinforced Concrete Beams,” (Detroit: Author, 1907).

C.A.P. Turner, Concrete-Steel Construction (Minneapolis: Farnham Printing & Stationary Company, 1909), 115-120.

C.A.P. Turner, U.S. Patent 1,003,384, filed June 11, 1907 and issued September 12, 1911.