From Conceptual Design to Implementation

Over the past 15 years, and particularly following the events of September 11th 2001, there has been increasing demand to incorporate blast resistance in important government and commercial facilities. Exterior walls of such buildings are designed to withstand blast impulse loading without a failure that would endanger building occupants, either through penetration of harmful debris or pressure waves. Operators of petrochemical facilities are also concerned about similar explosive threats due to large accidental explosions.

To resist these blast threats, designers have typically specified building envelopes comprised of reinforced concrete or masonry walls. Unfortunately, these walls are costly to build and are not amenable to portable construction, a frequent need for military applications. Recognizing this, the Department of Defense and several other agencies have expended significant funds to develop more economical, light-weight solutions to provide the needed personnel protection against explosive threats. Given their high strength-to-weight ratio, and low cost, cold-formed steel stud (CFS) walls would appear to be an outstanding alternative. These researchers have found that steel stud walls constructed using conventional detailing have limited blast resistance, due to premature buckling instabilities that develop in the studs. Attempts to enhance blast resistance of such walls through use of catenary behavior require expensive connections of the stud to the supporting structure, resulting in impractical and costly construction.

New Developments

A promising option can be found in ground breaking SEB-Wall Systems. SEB-Walls consist of conventional CFS studs sheathed with a composite cement board/steel plate sheathing material such as Sure-Board™ or equivalent, and with enhanced detailing. Simpson Gumpertz & Heger, Inc. (SGH) led an extensive experimental and analytical program to develop the SEB-Wall, and demonstrate its ability to resist high blast threats equivalent to large vehicle bombs or very long duration vapor cloud explosion events. The development program was managed by SCRA Applied R&D under the direction of Mrs. Polly Graham, and was jointly funded by the U.S. Army Research Laboratory (ARL) and the U.S. Air Force Research Laboratory (now Air Force Civil Engineering Center) at Tyndall Air Force Base, Florida. The SEB-Wall development program incorporated lessons learned from past programs on conventional CFS walls conducted by the University of California at San Diego (UCSD), University of Missouri-Columbia, Air Force Research Laboratory, Army Research Laboratory, Department of Defense, State Department, and other agencies. The experimental program demonstrated that the SEB-Wall displays significantly enhanced blast resistance, in comparison to conventional stud wall systems.

Initial physical testing for the SEB-Wall development and validation program included numerous blast simulation tests at the UCSD Blast Simulator facilities under the direction of Dr. Gilbert Hegemier and Dr. Lauren Stewart. This relatively economical and controlled test procedure avoids the use of explosive materials, and allows testing of specimens through multiple increasing impulsive force demands up to failure. UCSD tested, under multiple actuator impacts, a total of seven full-scale stud wall specimens using high-strength micro-alloy Vanadium steel (HSLA-V) as well as several mild steel stud walls during a previous testing program. The blast simulation tests assessed the response and capacity of two connection types and the effectiveness of different construction details in preventing premature failures and stud instabilities.

The second and third series of tests consisted of live explosive and quasi-static tests at the Air Force Research Laboratory at Tyndall Air Force Base, under the direction of Mr. Casey O’Laughlin. SGH coordinated, designed, and validated these tests under a wide range of blast demands using finite element analysis. The full-scale field tests confirmed the system’s application for retrofit of unreinforced masonry and as stand-alone construction. The field tests also allowed establishment of sheathing limit states under pressure and identified vulnerabilities in other wall components. SGH developed improved detailing requirements to ensure wall stability under direct pressures. The quasi-static load-tree tests of full-scale wall segments helped determine the static resistance functions of the composite stud-sheathing wall system for use in single-degree-of-freedom simulations. In this test setup, a hydraulic actuator load is distributed to 16 point loads equally-spaced along the length of the specimen, approximating uniformly distributed loading on steel studs. Exterior and interior composite sheathing in all three experimental phases consisted of Sure-Board panels (Figure 1).

Figure 1. Experimental program phases: (a) blast simulation tests at UCSD, CA (b) field tests under live explosives at Tyndall AFB (c) quasi-static load-tree tests at Tyndall AFB.

Analytical validation by SGH included explicit dynamic finite element analysis using ABAQUS. The analytical results matched the experimentally-obtained force and deformation demands within 10% accuracy. Based on these test results, SGH developed design tools and implementation guidelines for selection and detailing of SEB-Walls to effectively achieve target performance for specified explosive threat levels. Design guidelines, which include single-degree-of-freedom system approximations and construction specifications, will provide substantial broadening of the applicable range of response limits for stud wall systems previously specified by the U.S. Army Corps of Engineers Protective Design Center.

How does the SEB-Wall Work?

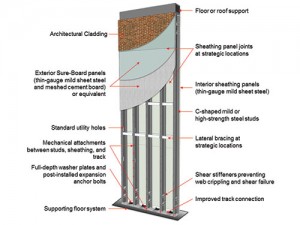

The system primarily comprises a conventional CFS wall with improved detailing to avoid undesirable failure modes, sheathed on both wall sides using composite sheathing. The sheathing provides important structural benefits to the system including composite action and lateral bracing of the stud, increasing the wall’s flexural capacity under pressure loading, and reducing the deflection demands and resulting wall damage. Critical SEB-Wall design details also include stud lateral bracing, use of strategically-located shear stiffeners, enhanced track or angle connections, and optional granular fill (Figure 2). The design resolves issues of thin steel section susceptibility to local buckling instability, premature shear failure modes, and net section fracture at high deformation demands, while exploiting the high strength-to-weight characteristics of steel. It also enables use of simple, economical, and practical connection details for wall anchorage to either concrete or steel supports.

Mild or High-Strength Steel

The program initially explored the feasibility of using walls fabricated from HSLA-V studs with strengths up to 100 ksi. The research showed that these high-strength walls provide satisfactory resistance to very high blast impulse loads. More common mild (33-50 ksi yield strength) steels in SEB-Walls were also investigated, and it was found that these materials also provide significantly enhanced blast performance relative to conventional walls. On average, the SEB-Wall system can be constructed at approximately 30% less cost than the more traditional concrete or masonry systems. The higher strength steels provide additional cost savings, for a given blast loading, relative to mild steel walls.

Composite Sheathing

The sheathing panels consisted of ½-inch thick meshed cement board adhered to 14 gauge mild steel. This sheathing is installed on the wall’s compression side, while a 22 gauge mild sheet steel is installed on the tension side. Together, this sheathing provides enhanced flexural stiffness and strength to the studs through composite action. The sheathing also assists in bracing of the studs and preventing lateral torsional buckling and other instabilities; and it strengthens the stud-to-track connection reducing susceptibility to full blow-out failure.

The location of plastic hinges along the length of the stud wall depends on the horizontal panel joint and utility hole layout. Best wall performance is obtained when multiple hinges form along the stud length as this distributes damage and avoids high stress concentrations at a single location, which may result in brittle net section fracture and penetration failure. However, due to initial imperfections present in all studs, and the susceptibility of thin gauge steel material to local buckling instabilities, and asymmetrical rotational stiffness, hinge formation along the wall height cannot be fully controlled.

The valuable contribution of the composite sheathing was evidenced throughout the experimental program and finite element simulations. Other sheathing types and layers of sheet steel are also beneficial in increasing stud stability and composite action but were found to be less effective than composite sheathing. The amount of composite action contributed by any sheathing depends on the stud material gauge and spacing, and fastener efficacy.

Enhanced Connections

Improved stud-track connections allow the SEB-Wall to resist high shear force demands developed under blast loading. Enhanced track connection details include increased track dimensions, multiple screw attachment between studs, track, and composite sheathing, full-depth and thick washer plates, while using post-installed expansion anchor bolts.

Limited tension-membrane stud resistance can be developed using the improved track connection under large stud wall deflections. However, the SEB-Wall does not rely on tension-membrane action for blast resistance. In fact, an alternative bearing connection detail was tested that provides no tensile resistance but is highly effective under extreme impulse demands.

Additional Details

To develop the wall’s full flexural capacity, it is necessary to prevent stud instability and premature failure and enhance the interaction of the various components. This requires somewhat different construction detail than typically used in CFS walls. These details include enhanced lateral bracing (i.e., blocking or notched-studs), and shear stiffeners near stud ends. The system allows general contractors and their curtain wall fabricators the flexibility of attaching the wall components by welding or mechanical fasteners such as self-drilling, self-tapping screws. The SEB-wall incorporates construction details developed for practical implementation with the assistance and feedback of cold-formed steel installers and manufacturers.

Why Choose the SEB-Wall over Other Blast Mitigation Systems?

High-Performance

The SEB-Wall system provides a four-fold increase in blast resistance relative to conventional CFS walls. The SEB-Wall design successfully resisted blast demands corresponding to a large vehicle bomb (with impulses in excess of 500 psi-msec). This considerably exceeds the capacity of conventional CFS walls with demonstrated explosive threat resistance limited to package bombs (with impulses of less than 100 psi-msec). The high-performance of the SEB-Wall system is comparable to reinforced concrete and masonry walls, precast/prestressed concrete panels, and advanced composite systems.

Cost-Effectiveness

With a total wall construction cost of $27/SF (including materials and labor and excluding architectural finishes) corresponding to on-site infill-wall applications, the SEB-wall provides approximately a 30% cost savings in comparison to other high-performance blast-mitigating wall systems including reinforced concrete, reinforced masonry, and precast/prestressed wall panels. Further material savings and reduction in construction costs (or alternatively enhanced blast performance) can be obtained through the use of HSLA-V or other high-strength steels.

Construction of SEB-Walls typically does not involve curing time or complex installation procedures with high indirect costs. The light weight of these systems also makes them more transportable than competing systems. As a result of these characteristics, the lighter SEB-Wall, designed to be ductile, redundant, and have predictable response, can in many cases provide a more economical solution than concrete or masonry walls.

Construction Benefits

The SEB-Wall can be used for retrofit of masonry or other existing wall systems with limited blast resistance, as well as stand-alone applications under direct blast pressures. It can be applied to protect building envelopes from external air-blast explosions using single- or multi- story panels. These systems, which can be installed on site or prefabricated and transported, can be used for expeditionary military applications as well as economically constructed site-built buildings. The practical and easy installation procedure, as well as the potential removal of the blast walls is feasible within this innovative system, allowing modular construction and reuse.

Ongoing and Future Efforts

The development program described in this article qualified the use of SEB-Walls as blast-resistant non-load-bearing elements. The US Army Corps of Engineers Protective Design Center still imposes strict limits on the use of CFS walls in load-bearing applications. These restrictive requirements (imposing elastic response limits on CFS walls and minimal rotational demands on their connections) were established due to a lack of experimental or analytical data supporting more liberal criteria. The Air Force Civil Engineering Center at Tyndall Air Force Base and SGH are developing a comprehensive experimental program supported by high-fidelity analytical simulations to enable resistance characterization of conventional and enhanced steel stud wall construction and validation of a new set of response limits for load-bearing applications.

Summary

The SEB-wall is an innovative and cost effective system proven to resist large vehicle bomb threats and long-duration vapor cloud explosion events resulting from distant accidental explosions. The SEB-wall system relies on the flexural capacity of either mild or high-strength steel studs, composite sheathing, strategically-located lateral bracing, and enhanced connections for wall anchorage, resulting in a practical and economical solution for blast protection. Special yet simple construction and installation details are crucial to ensure adequate performance of these non-conventional curtain wall systems.

The implications of the SEB-wall research and development program extend well beyond the Department of Defense and multi-national petrochemical industries. Many other governmental, commercial and residential applications can directly benefit from the use of this light-weight, high-performance and cost-effective wall system for building protection. In addition to cost savings of approximately 30% compared to other blast mitigation wall systems, additional benefits resulting from the use of the SEB-wall can include reduction in material quantities (reduced foundation size resulting from the use of lighter wall systems), simplified installation procedures, and expedited construction duration.▪

Acknowledgements

The SEB-wall research and development program was initially sponsored by the U.S. Army Research Laboratory under Cooperative Agreement DAAD19-03-2-0036 and managed by the Advanced Technology Institute dba SCRA Applied R&D. Additional funding and technical support was provided by the U.S. Air Force Research Laboratory (now Air Force Civil Engineering Center) at Tyndall Air Force Base, Florida for execution of field and quasi-static tests. Construction materials and labor for select tests were also donated by Intermat Inc. Any opinions, findings, and conclusions expressed in this material are those of the authors and do not necessarily reflect those of the funding agencies.