My love of Egypt and my first contact with Egyptian construction started in 1994 when I was asked to provide a scheme to strengthen parts of historic Cairo after the devastating earthquake in 1992. This initial contract was to work with the state-owned Arab Contractors to strengthen the Al Ghory Mosque, which had been extensively damaged. It was at that time that I was able to visit the Giza Plateau to see the pyramids.

My first view of the Great Pyramid was in the early evening when I got out of my vehicle at a local hotel. I was expecting to see a pyramid, but I was not prepared for the scale and size of the monument that was in deep shadow at that time of the day, almost obliterating half the sky. Like many other visitors, the first question that inevitably came to my mind was: ‘How could people with primitive tools build these fantastic monuments in such a short time?’ At that time, I did not take any professional interest in the construction of the pyramids, but I did feel a great deal of respect for the constructors.

Although we have been fascinated with how the ancient Egyptians built these incredible monuments, there is still a lot of discussion and mystery surrounding the actual method. The Step Pyramid of Djoser, which is 62 meters (203 feet) high, was the first high-rise structure that the ancient Egyptians built; previously, their structures were no more than 10 meters (33 feet) tall. How did the ancient Egyptians manage to construct the Step Pyramid, having never before erected a structure anywhere near that size?

My professional interest in the construction of the pyramids was initially sparked by observations that I made during Cintec’s work restoring the ceiling of the burial chamber of the Step Pyramid. We were called in to restore the ceiling, which was collapsing due to the failure of the timber beam that the ancient Egyptians had used to hold the ceiling stones in place (Figure 1). Our unique Waterwall airbags supported the dangerous hanging stones temporarily, and our patented anchors permanently secured them (Figure 2).

While in the burial chamber, I noticed that although we were drilling holes that were 4 meters (13 feet) in length, we never actually drilled through stones that were more than 40 centimeters (16 inches) wide. This appeared to be a direct contradiction of the common belief that the enormous stones on the outside were the same all the way through the pyramid. In some cases, the fill was a great deal smaller. It was this observation that prompted me to question the accepted theories that attempt to explain how the pyramids were built. Having worked in the construction industry for 54 years, I began to analyze these theories from a practical builder’s perspective.

I put myself in the mind of an ancient Egyptian builder faced with limited tools and little experience of large-scale construction. The main problem that I found with the existing theories was that, from a builder’s perspective, they made the process more difficult than it needed to be. Why would the Egyptians haul huge stones from a long distance away unless it was absolutely necessary? The internal core and filling would never be seen, so why fill it with quarried blocks that took time and presumably money to extract and transport to the site? The logistical problems were already enormous – coordinating all the elements from quarrying, transport, scaffolding, design, setting out and manpower requirements.

A Progression of Knowledge

Cintec has undertaken restoration work in both the Red and Step Pyramids in Egypt, and during this work I have observed the progression of the ancient Egyptians’ knowledge of construction techniques. With every pyramid they built, they became more skilled and corrected previous design defects. One such example is their use of corbelling to create openings in the pyramid for the burial chamber.

At the Step Pyramid, the builders attempted to create an opening for the chamber by using large timber beams. However, the timber buckled and failed, causing stones to fall. It was this failure that Cintec was brought in to correct. When the ancient Egyptians moved on to create the burial chamber ceiling in the next two pyramids, the Meidum and Bent Pyramids, they attempted to use a corbelling technique to overcome the failure of the timber beams. Both of these pyramids have unusual shapes; the Bent Pyramid’s top section sits at a slightly different angle to the main body, giving the structure its ‘bent’ appearance, while the Meidum Pyramid has the appearance of a truncated box sticking out of the ground, rather than the even slopes of the later pyramids.

Corbelling stone and masonry is now a well-known technique in construction. However, the ancient Egyptians were newly using it when building the pyramids. Therefore in both the Meidum and Bent Pyramids, the builders exceeded the overhang needed for the corbel arch to support the weight. This resulted in the burial chamber being squeezed together, and it is this mistake which I believe is the cause of both pyramids’ unusual shapes. The builders rectified it in the construction of the next pyramid, the Red (or North) Pyramid, which is a perfect example of the correct use of corbelling and has a true pyramid shape.

How Were the Pyramids Actually Built?

This progression of knowledge shows that the ancient Egyptian builders were pragmatists, and as such would have always built in the simplest and most efficient way they knew how. As stated earlier, I have found many of the existing theories on how the pyramids were built to be overly complicated and sometimes entirely impractical. I believe that they instead employed much simpler and therefore more viable methods than many current theories propose. It is my opinion that the pyramids were constructed using internal ramps, combined with some additional scaffolding, and not with enormous external ramps, a theory currently favored by many archaeologists.

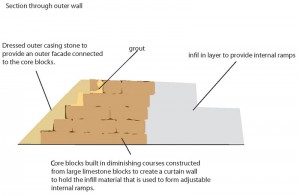

I believe that the pyramids consist of three different layers (Figure 3). First is the middle core that is visible on every pyramid after the Bent Pyramid. I predict that this layer is only three blocks wide, with the blocks diminishing in size as they near the apex. This layer was used by the Egyptian builders to retain the core filling and would have been a key to connect the outer cladding. The step design of the pyramid meant that the builders were able to connect the cladding to the pyramid while still supporting the weight of the cladding blocks.

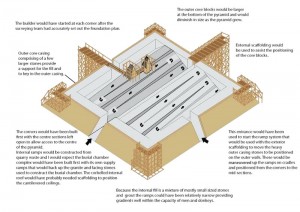

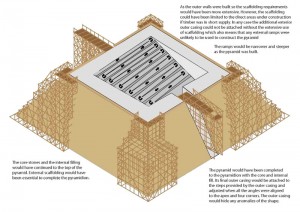

From my observations of the burial chamber of the Step Pyramid, I believe that the infill and central core of the pyramid primarily consist of much smaller stones, and any other larger blocks that the builders wanted to conceal. The inner core was used to create internal ramps, which enabled the Egyptians to build the pyramid from the inside out (Figures 4 and 5). The ramps were started at the mid-point of the pyramid and would zigzag across its full internal width, matching the height of the middle-core stones as the pyramid was built. The small number of heavy middle core blocks could have been raised on these internal ramps and positioned at the perimeter of the pyramid. As most of the inner fill stones were much smaller, they could have been easily handled by men and animals.

The ramps would get steeper as the pyramid grew in height, but they would not exceed the normal angle used to calculate the external ramp gradient. The ramps could have had small palm tree trunks partly embedded into them as a mechanism to slide the heavier core blocks on wooden sledges. As the pyramid reached the apex, more reliance on scaffolding would have been necessary to top out the structure.

The final layer is the outer cladding, which would have been added last and used by the ancient Egyptians to smooth the outer appearance of the pyramid and ensure its ‘true’ pyramid shape using additional stones or tufla grout, like the final icing on a cake.

Some people have been skeptical of any theory involving the use of scaffolding, as they argue that the ancient Egyptians would not have had access to enough timber. My method requires only a small amount of scaffolding in order to attach the outer cladding, and the same scaffolding could have been moved around the pyramid as they worked. In recent restoration work on the pyramids, traditional timber lashed together has been used as scaffolding (Figure 6), which demonstrates that it clearly would have been possible to use scaffolding to construct them in the first place.

Conclusions

I acknowledge that these are only my theories and not facts. However, there is a way to prove my theory of the layers of the pyramid, and I volunteer to carry out this work at no charge to the Egyptian Antiquities. We could diamond drill 100-millimeter (4-inch) core holes into the pyramid at varying heights to a depth of 30 meters (100 feet) and provide a drilling log of all the contents of the bored hole to establish the true nature of the fill. The drilling would be done with the latest dry drilling techniques to prevent damage to the pyramid, and the core would be plugged and filled to match the external appearance.

The short period of intensive construction by an ancient civilization who managed to build these wonderful monuments was remarkable. One can only admire the great ingenuity and effort that was required by a team of specialist builders, who from the very start showed great ingenuity and the ability to adapt, overcome problems, and learn from their mistakes.▪