Theodore Burr had just finished his Union Bridge in Waterford, NY (STRUCTURE, February 2014) when he was called to Trenton, New Jersey to build a toll bridge across the Delaware River just above the falls. The New Jersey Legislature passed an act for a bridge on March 3, 1798 and the Commonwealth of Pennsylvania passed a similar law on April 4, 1798, entitled “An Act to authorize the Governor of this Commonwealth to incorporate a company for erecting a Bridge over the River Delaware at or near Trenton.”

There was a high degree of risk involved in building a bridge over a major river that was noted for flooding and ice jams. This made it difficult to sell shares in the bridge company and sufficient funds were not raised to start construction until May 21, 1804 when the cornerstone was placed. Burr was given charge of designing and building a five span bridge over the Delaware River between then Trent’s Town (now Trenton) New Jersey, and Morrisville, Pennsylvania, thus making it an interstate bridge. He designed a variation of a tied arch with iron verticals and a large upper wooden chord made of laminated planking. His iron verticals were suspender chains similar to those used by James Finley in his suspension bridges of the time, in that they were a series of loops. The wrought iron loops were forged together into a chain to arrive at the proper length, inserted through the wooden upper chord and held with a pin.

Where did Burr get the idea for a tied arch in wood? Did he see his arch as a Finley Suspension Bridge reversed, or did he follow the statement of Thomas Young that “as the flexible chord hangs, so does inverted the rigid arch stand?” Did he know of a British patent #2,109 issued to James Jordan on May 24, 1796? Jordan claimed he could suspend “canal troughs or roadways from laminated wood or iron arches, the end connections to be so arranged that there was no thrust on the abutments.” Whatever the source, Burr designed and built a bridge that was unique to the United States, and one that was noted around the western world.

During construction, which began on May 21, 1804, the company built the piers and abutments to a height they thought was well beyond any height the Delaware River could reach. After completing the stonework, but before the wooden superstructure was begun, the Delaware rose to a height that covered the newly placed piers and abutments. The contractor immediately raised the stonework above the highest water just experienced.

James Mease’s Geological Account of the United States published in 1807 noted “The bridge at Trenton, over the Delaware River, thirty miles above Philadelphia, justly claims distinguished notice in the present work. It is to be regretted that the ingenious architect, Mr. Burr, had not given to the public a detailed account of a work of such great and general utility, the execution of which does him so much honour.” He wrote,

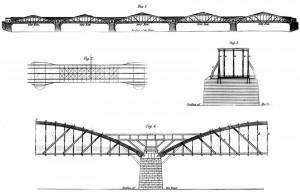

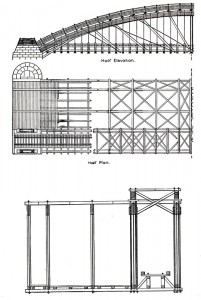

“The superstructure of the bridge consisted of five wooden arches, respectively 203, 198, 161, 186 and 203 feet in the clear, each composed of five great arched ribs rising from the chord in the proportion of 13 feet to 100. These ribs were made of four-inch pine planks, a foot wide and from 35 to 50 feet long, built up into a thick, laminated rib, three feet wide [deep]. The relative placing of these ribs left two openings of 11 feet each in the center of the bridge for carriage ways, and two more, each 4 feet 6 inches wide on the sides for footwalks. The ribs were spaced and bound together on the top circumference of the arches by ties and diagonal braces, fastened to the ribs by bolts and screws at intervals of 8 feet. The floor was suspended from the ties by perpendicular iron rods, securely fastened in the wood. Wing arches and diagonal braces were effectively used throughout to eliminate all motion between the parts of the bridge, thus making it a rigid and solid structure.

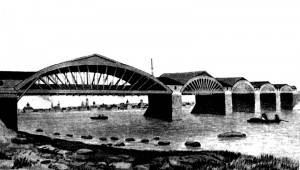

The entire bridge was covered by a roof of cedar shingles, and was enclosed at each end. Originally there were high and elaborate fronts, both on the New Jersey and the Pennsylvania ends of the bridge, with great arched doorways over the carriageways and footwalks. Balustrades four feet high ran along the whole length of the bridge, outside of the footwalks, to protect the pedestrians.

The bridge rested upon the abutments and four piers, all of stone. The piers were made about one-fourth higher than they had originally been planned…The ends of the piers upstream were semicircular and, after rising five feet, gradually receded to the top, where they were finished off in a half-dome. These piers were 62 feet long and 20 feet deep.”

Herman Haupt, in his 1851 book on Bridge Construction, wrote that the diagonals were inserted and anchored into cast iron shoes at the lower end, and tied to the upper arches with iron straps acting as counter braces [ties]. They were twin 6 x 10-inch timbers, spiked to the lower chord and secured to the arches by long 2-inch by ½-inch iron straps… and indicated the links of the suspenders were of 1-1/8-inch square bars, about 4 feet long and 5 inches wide, passing flatways through the arches and between the chords and counter braces; a key passing through the link on the top of the arch.

The lower chord was made of a pair of 6-1/2 x 13-1/2-inch timbers and, again according to Haupt, “are connected by means of long straps of iron passing around the end of the arch at the skew-back, and bolted through the chords.” Haupt also described what he called spur arches, noting: “On the sides are large spur arches of the same dimensions of the main arch of the truss, extending from a point 8 feet outside of the truss on the abutments and piers, and terminating within 44 feet of the centre-spiked at the point of intersection of the arches of the main truss.” In summary, the arches were supported by a combination of the diagonal ties, tension chords and bearing on the piers and abutments.

Mease continued his write up of the bridge by stating, “the three great objects, convenience of travelling, strength, and durability, are all happily united in the model adopted…nor has ornament been wholly thrown aside. The access to the Bridge, on either side, and throughout the whole extent of the platform, presents to the traveller a plane, without any sensible rising.”

Mease finished his report on the bridge with:

Our bridge, we are assured by Mr. Burr, combines double the strength of either [Waterford or Fort Miller] of them; but what constitutes the greatest excellence of the Delaware bridge, is the prospect of its durability… the permanency of the stone work is not to be questioned, and by the proposed covering, the stamina, or main parts of the wooden superstructure, will be effectually protected from decay by the wet, while those parts we exposed to injury from the weather, are all susceptible of the most complete repair.

The entire structure was roofed shortly after construction. Instead of the standard gabled roof running along the axis of the bridge, Burr used a conventional gable over his piers with a gabled roof running transversely over his arches. The only walls that were covered were over the piers, leaving the arches exposed on the side. The primary reason he did not cover his walls and have the normal gable roof over his arches, besides cost, was the large wind loads that would have made if difficult, if not impossible, to brace the arches.

The bridge was opened on January 30, 1806 to a large celebration that was described in the United States Gazette on February 5, 1806:

On Thursday the 30th ult. the bridge over the Delaware River near this place was opened to the public. The collection of people assembled on this pleasing occasion was great. A procession was formed, commencing at the house of Amos Howell, from whence they set out at 12 o’clock.

Burr and his workmen led the parade across the bridge, while 17 cannons [one for each state in the Union] at each end of the bridge fired throughout the procession. Once across the bridge, the entire procession switched from foot to carriages and came back across the bridge in the same order. When they returned, a ceremony was held primarily to honor Burr and his men. The President of the bridge company made the following address:

To you sir, as their principal architect, great commendation is due, for the fidelity, zeal, and unremitted industry, you have manifested in the superintendance and judicious management of this important and arduous undertaking; being your self equally expert to work in stone and in iron as in wood, you have given a direction and energy to each of those branches which tended greatly to facilitate their progress.

The skill and ingenuity discovered in the design and plan of our bridge, has already been the subject of high encomium by a discerning public, as well as by the Board; and it now only remains for them to testify their entire approbation of the masterly stile in which the workmanship in every part appears to be executed, but as it regards neatness and strength, to those who are judges of architecture the simplicity and justness of the plan of our Bridge, and the order and symmetry of its structure, cannot fail to be highly appreciated, while to those artists in the science of Bridge building, it must prove a valuable model and worthy of future imitation…

At a reception Abraham Hunt made another toast to Burr as follows:

Theodore Burr – may the Trenton Delaware Bridge prove as useful to the publick, as the simplicity and strength of the plan, and the skill and ingenuity displayed in the workmanship thereof, will reflect credit on its Chief Architect.

David Stevenson, a noted British Engineer, visited the bridge about 30 years after its opening and obtained a copy of the drawings. He reproduced them in his 1838 Sketch of the Civil Engineering of North America, Comprising remarks on the harbours, river and lake navigation…and other works in that country. He gave a detailed description of the bridge and brought the design to an audience in England, but there is no evidence that anyone in England picked up on this design.

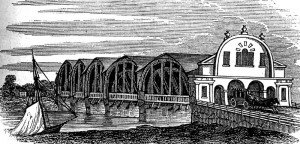

In 1835, rails were laid on the north wagon road, and trains, generally hauled by horses, crossed the river. This required the southerly carriageway to handle two-way traffic on a width that was inadequate. In the summer of 1848, a decision was made to widen the bridge to accommodate two-way carriage traffic, one sidewalk and one railroad track. To handle this additional traffic, they simply removed the roof, all overhead bracing and the deck structure between the two southerly most arches. Then they moved the southerly arch five feet south on the existing piers that were wide enough to accommodate this shift. They strengthened the two southerly arches by placing additional arches of planking over them and bound the new arches to the old with short ties. After the arches were strengthened, they placed new overhead bracing to stabilize them.

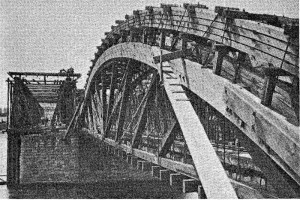

Picture looking at southerly side of bridge with reinforced arches for railroad, beginning of iron truss bridge on left.

In the great Delaware River flood of 1841, only Timothy Palmer’s Easton Bridge, opened in 1806, and Burr’s Trenton Bridge survived. A steel bridge was built on the enlarged piers for the Pennsylvania Railroad in 1892. In 1898, another parallel steel railroad span was built on expanded piers, making a total of three lines of trusses on the same piers. The two railroad spans were removed in 1903 when an adjacent concrete arch bridge for the railroad was built. The current vehicular bridge, called the Lower Trenton Bridge, was built in 1928 on Burr’s piers and is illuminated with a sign stating, Trenton Makes the World Takes.

Burr went on to build many bridges across the Mohawk, Susquehanna and other rivers. All of these, however, were similar to his Waterford Union Bridge. He never used the Trenton Bridge design in the future, even though it was a success.▪