Frank Heger was a vanguard of the engineering industry, a visionary with his work, and a champion for public safety. From the late 1970s to 1982, the author witnessed the evolution of Frank’s most well-known work in geodesic spheres, “Spaceship Earth” at Disney’s Epcot Center. In 1980, he developed the revolutionary Soil-Pipe Interaction Design Analysis (SPIDA) software – the first-ever computer program combining heavy mathematical and theoretical computations for the design of buried pipe systems. In addition, Heger performed outstanding investigative work for the L’Ambience Plaza Collapse in 1987, which led to receiving the 1992 Construction Index Excellence Award for his personal research into the matter.

From 1955 to 1963, Heger served as an associate professor at Massachusetts Institute of Technology (MIT). In 1956, he joined two of his MIT colleagues, Werner Gumpertz and Howard Simpson, to found Simpson Gumpertz & Heger Inc. (SGH). The author personally was fortunate enough to spend over two decades under Frank’s tutelage, working on projects which were challenging, iconic, and innovative. The following highlights just a few of his many tremendous achievements.

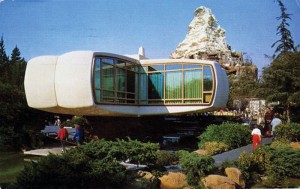

House of the Future

After World War II, the United States had grown weary of years of turmoil, and the Walt Disney Company sought to provide some relief. Disney enlisted the Monsanto Chemical Company to construct a solar-heated house made entirely out of plastic, a rarely used, ultramodern material for the time. In turn, Monsanto asked Marvin Goody at MIT’s Plastics Research Laboratory to help design the house. Part of the expectation was to change the perception of plastics from a cheap substitute material to a high-quality engineered material that would keep construction costs down and achieve modern results. Thus, the year 1954 proved to be a turning point in the use of structural plastics.

Heger was an assistant professor at the time and was put in charge of structural engineering on the project. He partnered with fellow MIT professor, and frequent collaborator, Albert Dietz. Despite modest knowledge of plastics, the two engineers determined that the structure had to be especially stiff, and that creep and deformation due to long-term loads had to be carefully predicted. They paid close attention to dead weight, live loads, wind loads, snow loads, earthquake loads, and thermal stresses due to a possible 100º F difference in temperature between the exterior and interior. The uneven nature of solar heating and the inability of fiberglass-reinforced plastics (FRP) to yield before failure added significantly to the project’s complexity.

Heger and Dietz designed the house to have a central core with four symmetrical cantilevered wings. The wings, floor, ceiling, and roof of the house were constructed as a continuous piece to provide the greatest stiffness and strength using the least amount of plastic. The designs of the walls and cross-sections were based on a careful analysis of forces within the structure.

The lead-up to construction included a host of tests. A six-week strain and deflection test under the full design load of 50 psf showed no appreciable creep. Other laboratory tests demonstrated that materials could bear a 75º F heat differential, nearly double the planned loads for a forty-eight hour cycle, with no tendency to creep or otherwise malfunction. The demonstration house at Disneyland would be the real test. Millions visited the house during its decade-long life as an attraction. When set for demolition, it was said that a wrecking ball bounced off the house. It was eventually cut apart by hand. The project’s success heightened Heger’s burgeoning reputation as an authority on structural plastics, leading to decades of work on future projects.

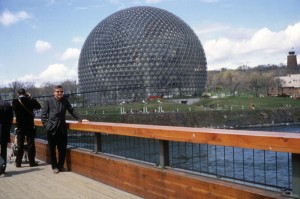

Expo ‘67

World Expositions (Expos) offered a chance for the international community to showcase cultural and societal pride. In the 1960s, amid great international tension due to the Space Race and other issues, the U.S. pavilion planners for the Montreal Expo ’67 sought to create a technically complex and memorable structure. They asked visionary architect Buckminster Fuller to design the pavilion.

Fuller first proposed a dome-shaped pavilion making use of tensegrity, an experimental design geometry he had developed involving a series of rods and cables assembled so that tension and compression members alternated in a series. The concept’s unique nature meant that no one instinctively knew if the design would work. Fuller and the planners needed someone with structural engineering expertise to make the necessary design computations, and their search led them to Heger.

The team ultimately decided to pursue a geodesic geometry and designed a 250-foot-diameter, three-quarter geodesic sphere. Until this point, mapping geodesic geometry onto a sphere had never been attempted for anything so large in scale. Heger’s design and calculations served as invaluable contributions.

The construction of the dome posed many challenges. The drawings called for the entire structural skeleton to be exposed, evoking latticework, so all of the members from top to bottom needed to be uniform in appearance. However, because the highest members did not require much strength in comparison to lower components, using uniform members throughout the dome would have been inefficient. Heger innovatively chose to design the dome using hollow cylindrical tubes to keep a uniform appearance while minimizing material. Moving down the sphere, he designed cylinders with increasingly thicker walls, until the members at the bottom of the dome were solid.

In response to the architects’ desire for a lacy aesthetic, Heger and his team conceived, designed, and tested a novel system of welded cast steel hubs for the individual joints. Like the dome’s members, the hubs had to support the dome, as well as contribute to its appearance. To be sure of the hubs’ strength, Heger designed and built a testing machine that would apply the peak values of compression and tension forces expected within the dome.

Heger envisioned a structure that was inherently stable during construction, and he spent a good deal of time convincing the construction crews that, because geodesic domes are self-supporting, external scaffolding was unnecessary. The contractor reluctantly agreed and proved him correct when construction was completed without issue.

SPIDA

Heger recognized that buried infrastructure is the life-line of our society, and ensuring the long-term performance of buried infrastructure components and systems requires a thorough understanding of structural behavior, material response, and the effects of the environment. He capitalized on his experience with materials and structural behavior to advance the industry in the design and investigation of buried pipes. In the late 1980s, the American Concrete Pipe Association (ACPA) approached Heger and SGH to design a computer program that would analyze soil characteristics and design pipes.

Heger’s understanding of pipe technology and design showed in the innovative solution that he developed for the ACPA. Using three-point tests, full-scale tests on both embankment and trench-laid pipe, and his broad knowledge of constitutive soil properties, he created a computer program called Soil-Pipe Interaction Design and Analysis (SPIDA). Designers could use it to analyze pipes and soil as separate but interconnected systems, and to evaluate the necessary reinforcement for a pipe based on these analyses.

Frank’s revolutionary software was the first that could execute complicated mathematical and theoretical computations in the design of buried pipe systems. Engineers no longer had to calculate the forces on each section of pipe by hand, as SPIDA could solve these equations at an unprecedented speed, allowing engineers to design pipe networks quickly and confidently. The development of SPIDA also led to the discovery that pipes buried using the sloped-wall trench method needed nearly twice the reinforcing steel as similarly situated pipes buried using the vertical trench method. Before the creation of SPIDA, it was believed that these methods required the same amount of steel.

Simpson Gumpertz & Heger

Heger enjoyed more than four decades working in the field that he loved with his closest colleagues. He often said that SGH’s success was because he hired people who were smarter than he was. The author always found this curious coming from a true genius. It is doubtful that he ever succeeded in hiring anyone who surpassed his intelligence and vision, but it reflected Frank’s attitude toward working with people.▪