Specified and Used Regularly for Reinforced Formed Members

Self-consolidating concrete (SCC) is increasingly used for reinforced formed-members, architectural concrete, and floors and slabs. It is often the only solution for structural repairs. SCC is a highly flowable, non-segregating concrete with a slump/flow of 20 to 30 inches. SCC can be easily placed and completely fills forms under its own weight without mechanical vibratory consolidation.

Self-consolidating concrete is achieved by use of the proper dosage of a high-range water reducing admixture and a viscosity-modifying admixture when needed to ensure stability and eliminate bleeding and segregation at the target spread. A high-range water reducer plus a hydration-control admixture may be used. A hydration-control admixture can extend proper plasticity for several hours.

Proposed mixes generally list the target spread as plus/minus 2 inches. The design/contracting team agree on a target spread. The target spread is the diameter of the concrete after the slump cone is raised. SCC is defined as concrete with a spread of 20 to 30 inches after the cone is lifted. In heavily reinforced members, the design/contracting team often requires a target spread of 28 inches +/-1 inch. In many tall buildings, the self-consolidating concrete mix used in vertical members is also used in slabs. Having one mix eliminates the required coordination of the switch from the vertical mix to the floor mix.

Proper consolidation of a conventional mix requires two men. One is vibrating, and the other is moving the vibrator from point to point. Therefore, the SCC mix is more economical. SCC usage means an increase in the volume of daily placements. More concrete can be placed in a typical workday with a smaller crew.

Maximum rental space is the goal in many buildings. Columns and walls are heavily reinforced and are as narrow as possible. SCC is a requirement. Example projects include a 14,000 psi concrete at Tower One at the World Trade Center in New York City. Almost all of New York City’s tall buildings are using 14,000 psi concrete in their vertical members at the lower floors. An 8000 psi SCC mix was pumped blindly into a heavily reinforced elevated slab under the active Number 1 subway line at the World Trade Center. The slab was 50 feet wide. Every truck had to have a 28-inch spread. A lower spread could have resulted in a blockage, and that would have been disastrous. The Port Authority made a video of the early placements so that the team could see the SCC mix move easily into place.

Architectural concrete is increasingly using SCC. The American Concrete Institute’s ACI 347, Guide to Formwork for Concrete, has included guidance for determining form pressure. The Eli & Edythe Broad Museum at Michigan State University, Columbia University Medical and Graduate Education Building, and the United States Mission to the United Nations (USUN) are good examples of the use of SCC in successful architectural concrete projects. None of these projects had form pressure problems of significance that required concrete removal and replacement. The architect of the Michigan State University, Zaha Hadid, required “no bugholes.” (Bugholes are small holes or voids in the concrete surface. They are +/- 1⁄8 inch plus/minus in diameter.) The solution was to have the SCC in every truck have a 28-inch spread.

Proper Planning

Before the start of each new project, the contractor and design team should conduct a pre-concrete construction meeting to review the proposed mix designs and to discuss the required methods and procedures to achieve the specified concrete construction. The contractor should require responsible representatives from all stakeholders concerned with the concrete work to attend the conference, including but not limited to the following:

- Contractor’s Superintendent

- Structural Engineer

- Ready Mix Concrete Producer

- Admixture Manufacturer

- Concrete Subcontractor/Finishing Foreman

- Concrete Pumping Equipment Manufacturer

- Laboratory responsible for field quality control

- Independent testing agency responsible for concrete design mixtures

The contractor should send a pre-concrete conference agenda to all attendees before the scheduled date of the conference. A typical agenda would include the following:

Special SCC Mix Design Requirements

- 28 day or 56-day strength.

- High early strength ____ psi @ ___ hours.

- Shrinkage – 0.04% @ 28 days is standard. 0.02% @ 28 days as noted on the drawings (This is the minimum standard if less shrinkage is required and minimal control joints are desired.)

- Freeze-Thaw/Durability

- Concrete receiving moisture sensitive floor coverings:

-Water Cementitious Ratio < 0.45

-High Range Water Reducing Admixture, Hydration Control Admixture

-Fly Ash and/or Slag are required in many mixes (normal set is required for floor mixes). Normal setting concrete will allow the concrete contractor to perform the required finishing operation properly within four to five hours after placement. The supplementary cementitious content, i.e., fly ash and/or slag, may be lower in floor mixes than in formed members since these supplemental cementitious materials tend to slow down the setting of concrete.

The concrete contractor should state that the proposed mix designs will enable proper placement, pumping, and finishing, and will achieve the concrete quality required by the specifications. The concrete producer should provide a high range water reducer re-dosage chart and a significant quantity of high range water reducing admixture on site to ensure that unexpected delays do not result in a concrete placement with spreads below the agreed upon spread/envelope. Hydration control admixtures can maintain the proper spread and workability for several hours, which allows the concrete producer to stabilize concrete mixes for long periods without negatively affecting concrete durability.

Proper mix designs and successful test placements onsite to verify proper workability, pumpability, setting time, and finishing are required on all high-performance concrete projects. Setting times and spread targets are adjusted as necessary for the change of seasons. When the planning and preparation are thorough, and appropriate Quality Assurance/Quality Control (OA/QC) procedures are followed, a very successful project is the result.

SCC Usage Today

SCC is also more economical because the crew requires two fewer people. The spread of placement and optimum crew size are of great concern for the concrete contractor. Many concrete contractors now know that the SCC cost-in-place for reinforced formed concrete is lower and the end product is superior compared to continuously placed and vibrated concrete. Early strength gain is essential on most projects to conform to an agreed upon rapid cycle schedule.

The Federal Highway Administration (FHWA) continues to work with the states, researchers, concrete industry, admixture suppliers, and other partners in advancing SCC technology through research development, deployment, and construction projects. Many states are using SCC in beams and girders, bridge piers and pile caps, columns, walls, and drilled shafts. SCC is also used in the repair of concrete members with limited access for conventional placement and vibration techniques.

SCC has many technical, economic, and environmental advantages. It can help solve some difficult and costly field problems and should be given consideration when the concrete involves:

- Intricate and complex formwork

- Congested steel reinforcement

- Architectural features

- Pre-Cast elements

- Need for quality, speed, and high productivity

- Limited access for proper vibration

The use of SCC in North America is increasing at a steady rate. It is similar to the automatic transmission in a car. Very few people choose a stick shift car or choose concrete mix for reinforced formed members that requires vibration.

SCC benefits include speed of job site production, ease and speed of placement, faster turnaround time of concrete trucks, elimination of vibration and noise, lower water content, and results in high performance and long-lasting structures.

For sustainability, SCC is the optimal concrete mixture. SCC mixes tend to be more efficient because of the higher rate of cementitious efficiency (psi/lb. of cementitious). It benefits from the use of significant quantities of supplementary cementitious materials such as fly ash, slag, and silica fume. Cement content can be lowered. The water content is lower. Conserving water is a priority all over the world.

As an example, for the 1,776-foot-tall Freedom Tower, the cement content of the 14,000 psi @ 56 days was 300 lbs/cy. (Total cementitious content was 873 lbs/cy). The water content was 220 lbs/cy. The project averaged 16,160 psi at 56 days.

Typical concrete, i.e., 3000 psi or 4000 psi concrete, with ¾-inch aggregate requires 290 pounds of water/cubic yard for a 3-inch slump. At the Freedom Tower, the water savings was 70 lbs/cy for 40,000 cubic yards of concrete = 280,000 pounds of water saved (33,533 gallons).

SCC results in a stronger, more durable concrete in place. Its use ensures easier and better consolidation, which results in a longer lasting concrete. The elimination of vibration provides a safer workplace with less noise and less damage to the hands and arms of the workers vibrating the concrete.

Successful SCC Projects

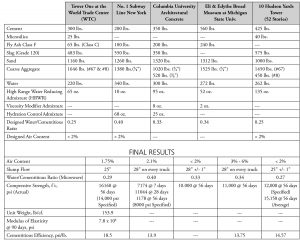

The Table gives a summary of five recent successful SCC projects. These proposed mix designs were confirmed by successful trial placements onsite for architectural concrete and heavily reinforced members.

- Tower One at the World Trade Center (WTC): 14,000 psi @ 56 days was required for the shear walls from the foundations to the 30th floor.

- No. 1 Subway Line: Another challenging SCC was the new 3-foot-thick slab under the No. 1 subway line, which runs through the World Trade Center. A very heavily reinforced slab, 50-feet-wide, was required. The SCC mix was successfully pumped into this location blindly. Cameras were installed to observe the complete filling of the new slab.

- Columbia University Medical and Graduate Education Building, New York: SCC in use – Sloping Columns.

- The Eli & Edythe Broad Museum at Michigan State University: This was another challenging architectural concrete project because of inclined forms. ACI 347 has included guidance for determining form pressure. Kamal H. Khayat and David Lange addressed the form pressure subject in their presentation at the International Workshop Conference, Self-Compacting Concrete, June 1st, 2012, in Stockholm, Sweden. Both Kamal Khayat and David Lange are world renowned authors and experts on SCC.

- 10 Hudson Yards, New York (52 Stories): New York City Concrete Industry Broad Grand Award Winner 2016.

Conclusion

Many specifications require a maximum shrinkage of 0.04% at 28 days. SCC mixes can be designed for very low shrinkage (0.02% at 28 days) by adding a shrinkage reducing admixture. That very low shrinkage is often specified for exposed slabs and toppings and concrete below the waterline. The goal is to reduce joints and cracks.

SCC dramatically expands the possibilities of successful high-performance concrete placements with difficult and demanding requirements. In fact, the goal in North America is to have SCC become 15% of all ready-mixed concrete. This goal, set by the Industry Critical Technology Committee (ICT is part of the Strategic Development Council (SDC), a council of the ACI Foundation), is being achieved in more cities because of use in tall buildings. All major design firms today specify SCC for architectural concrete and heavily reinforced members. The benefits of SCC are recognized by many owners, designers, and concrete producers throughout the country. A leading repair contractor in the United States will not form and pour without SCC. A prominent concrete contractor in the Carolinas is using SCC regularly in wall placements to ensure a uniform finish and economy and speed of placement. Most structural engineering firms today include SCC in their master specifications.▪

References

Influence of SCC Mix Design on Thixotropy by Kamal H. Khayat, P.Eng., Ph.D., FACI, Frilem, Director,

Center for Infrastructure Engineering Studies at Universite de Sherbrooke, Quebec, Canada.

Mechanisms of SCC Formwork Pressure by David A. Lange, University of Illinois.