Masonry has a long performance history as a durable, economical, and attractive building system. It has been used successfully in all climates and can serve as both the structural system and architectural finish. Construction today requires materials that are easy to use and have dependable performance, so manufactured masonry units that have uniform size and properties are much more common than natural (stone) units. Similarly, portland cement-based mortars and grouts are preferred for their consistent setting and strength characteristics.

Portland cement is found in mortar, in grout (when used), and may be an ingredient in units. With the push toward sustainability, materials such as fly ash are increasingly finding their way into masonry materials, especially by reformulating grout mixtures to include both portland cement and fly ash. Targeted research was undertaken to learn whether mixtures containing high volumes of supplementary cementitious materials (SCMs) could still produce the required strength for grout. This article summarizes the results of many years of research on this topic.

SCMs for Masonry Grout

Grout is a fluid mixture of cementitious materials and aggregate for use in fully or partially grouted masonry construction. The cementitious materials typically include portland or blended cement, fly ash, and slag cement. Conventional grout is made fluid by the addition of water, whereas self-consolidating grout (SCG) relies on chemical admixtures (and sometimes high powder contents) to achieve a highly flowing state. Grout fluidity is important to ensure uniform filling of block cells, which often contain reinforcing bars that may impede the flow of material. There is little distinction between conventional grout and SCG in the hardened state. The standard that guides the production of both conventional grout and SCG is ASTM C476, Standard Specification for Grout for Masonry.

TMS 402/602, Building Code Requirements and Specification for Masonry Structures, requires that grout compressive strength (at 28 days) be a minimum of 2000 psi or equal the compressive strength of masonry, whichever is greater (TMS 402/602 2016).

This article focuses on conventional grouts formulated with portland cement plus high volumes of fly ash and slag cement, both of which are considered SCMs. Replacing a portion of cement with SCMs helps reduce the environmental impact of the grout. For concrete masonry systems, grout mixtures are the best opportunity to introduce SCMs; the most common SCMs for this purpose are fly ash and slag cement. Prescriptive requirements of ASTM C476 allow for fly ash to be used up to the limit specified for an ASTM C595 portland-pozzolan cement (Type IP), which is 40% by mass of cement. For ASTM C595 portland blast-furnace slag cement (Type IS), the limit for slag is 70% by mass of cement. Researchers believed they could exceed those limits (which C476 allows by the specified compressive strength method) and still produce an appropriate grout strength.

Fly ash is a by-product of the combustion of pulverized coal in electric power generating plants. Fly ash for use in grout must meet requirements of ASTM C618, Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Slag cement, previously known as ground, granulated blast-furnace slag (GGBFS), is the glassy material formed from molten slag produced in blast furnaces as a byproduct of the production of iron used in steelmaking. Slag cement must meet requirements of ASTM C989/C989M, Standard Specification for Slag Cement for Use in Concrete and Mortars.

Impacts on Fresh and Hardened Properties

Fly ash and slag cement typically impact both fresh and hardened properties of concrete and grout. The effects of SCMs on hardened properties depend on several factors, including the composition and amount of SCM, the chemistry of the cement, the mixture proportions, and temperature during construction and curing. Each of these considerations should be well understood so that specifiers make informed decisions about SCM usage.

There are two classes of fly ash; Class C has both pozzolanic and cementitious properties, and Class F has only pozzolanic properties. The research described in the studies noted here all used Class F fly ash. Because Class F and C fly ashes behave differently in certain aspects, it is important to know whether you are using Class F or Class C when formulating grout mixtures.

All fly ashes and slag cements improve the workability of grout. Class F typically delays setting time and results in slower strength gain at early ages. Class C may increase or decrease setting time but does not have much impact on early-age strength gain. Both Class F and C contribute to better long-term strength. Slag cement also increases setting time. In concrete, Class F is often dosed at 15% to 25% and Class C is used at dosages of 15% to 40% by mass of cementitious material.

The pozzolanic and cementitious properties of SCMs influence the temperature during construction and curing. Class F fly ashes are likely to be more affected by cold temperatures, further slowing strength development. Class C fly ashes and slag cement are less affected by cold temperatures. It is imperative to understand the effects of the fly ash on the curing of the grouted masonry wall, as the potentially slower strength gain needs to be factored into the construction sequencing. It is also possible that cold weather protection may need to be extended, although there is no code requirement mandating this.

Performance of Grouts with SCMs

For grouted masonry, researchers wondered if it would be possible to add much higher dosages of SCMs to grout (known as “high-volume” substitutions of fly ash or slag cement) to reduce the environmental footprint of the wall while maintaining its performance. Researchers looked at varying dosages of SCMs (including by weight and by volume percentages), different combinations of fly ash and slag cement, the influence of dry and wet curing, and age at testing to determine limits at which effective performance could still be maintained. Fonseca and Siggard (2012) found that grouts with up to 40% Class F fly ash, and 80% Class F fly ash plus slag cement, perform as well as conventionally proportioned masonry grouts. The same study also found that 60% fly ash and 85% fly ash-slag mixtures can achieve the minimum required compressive strength of the grout mixture at 56 days, which can be an option for structures that will not be loaded until later ages.

Fonseca and Siggard described five phases of research into SCM replacement grout:

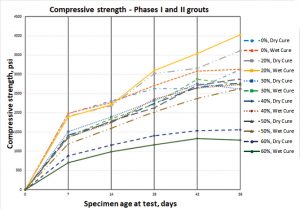

- Phases I and II: 0% – 60% fly ash (Figure 1)

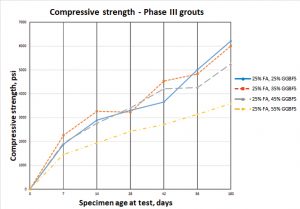

- Phase III: 50% – 80% fly ash plus slag cement (Figure 2)

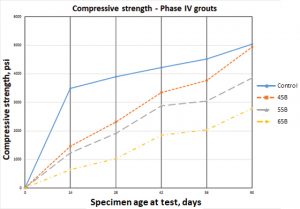

- Phase IV: 45% – 65% fly ash (Figure 3)

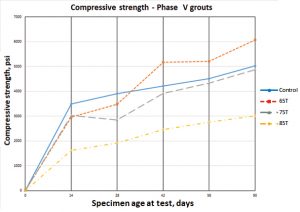

- Phase V: 65% – 85% fly ash plus slag cement (Figure 4)

As part of their research, grout was cured under both wet and dry conditions for the Phase I mixes (CMACN 2009). With little-observed difference between wet- and dry-cured strengths, grout mixtures for Phase II and subsequent Phases were only wet cured. The results show that grout with replacement of 50% (by volume) of the portland cement with a Type F fly ash meets the minimum requirements of the building code at 28 days (2,000 psi). At between 42 and 56 days, all mixture proportions with up to 50% replacement equaled or exceeded the strength of the baseline mixture that contained 100% portland cement. It is interesting to note the significant drop-off in the strength of the fly ash mixture that replaced 60% of the portland cement, which indicates the importance of knowing local materials and doing testing so that grout properties are well understood.

Phase III grouts were also wet cured (Figure 2). Here, fly ash was dosed at 25% replacement of cement by weight, with fly ash plus slag at 50%, 60%, 70%, and 80% portland-cement replacement. All of these mixtures were able to achieve the minimum 2000 psi grout compressive strength at 28 days.

Summary

Masonry construction offers numerous benefits. Properties include long life, durability, and strength. Resilience has been growing in importance as people recognize that the current focus of building codes is life safety and that it is possible to strengthen codes so that we also protect property in the face of many types of disasters.

High-volume SCM grouts, described in the research discussed here, achieved the required compressive strength within typical construction ages. The key benefit of this approach is to enhance masonry’s environmental footprint by replacing a portion of the portland cement in the grout with SCMs. No matter how masonry is built, it is a cost-effective, safe, and attractive system for a wide range of applications.▪

References

Fonseca and Siggard 2012: Fonseca, Fernando S., and Siggard, Kurt, Replacement of Portland Cement with Supplemental Cementitious Materials in Masonry Grout, 15th International Brick and Block Masonry Conference, Florianopolis, Brazil, 2012.

TMS 402/602 2016: Building Code Requirements and Specification for Masonry Structures The Masonry Society, Longmont, CO, 2016.

CMACN 2009: Masonry Chronicles Summer – Fall 2009, “Going Green with Concrete Masonry Grout,” Concrete Masonry Association of California and Nevada, Citrus Heights, CA, 2009.