Award-Winning Design Showcases Accelerated Construction Technique

When Dodge County was faced with two deteriorating bridges requiring replacement, coupled with cutbacks in infrastructure funding and a decreasing budget, they looked at implementing a new accelerated construction technique called Geosynthetic Reinforced Soil – Integrated Bridge System (GRS-IBS). What they learned is that, for qualified structures, implementing GRS-IBS can save time, money, and resources.

Dodge County, like many rural counties in Wisconsin, was struggling with how to fund their badly needed bridge repairs and replacements. Working closely with the Wisconsin Department of Transportation (WisDOT), the two agencies determined that, if they paired two of the county’s bridge replacement projects together, they had a unique opportunity to participate in the Federal Highway Association’s Every Day Counts (EDC) Accelerated Bridge Construction (ABC) program. The EDC program was developed to identify innovations that can speed up the delivery of highway projects, as well as address shrinking budgets.

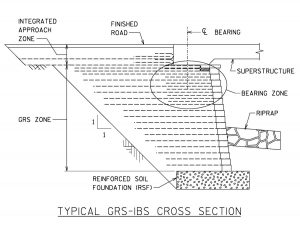

The Dodge County bridges met the requirements for using an accelerated construction method, GRS-IBS, developed by the Federal Highway Administration (FHWA). They were both small, single-span bridges over low flow waterways. Constructed in 1947 and 1950, the bridges were at the end of their useful life and were structurally deficient due to the poor condition of the steel girders and timber abutments. GRS involves building a reinforced soil foundation for the abutments, which eliminates the need for traditional concrete abutments and piling. IBS is a method of bridge construction that blends the roadway into the superstructure support. The geotextile reinforcement is gradually lengthened from the lower layers to the top layers to provide a smooth transition from roadway to bridge.

Projects can be completed in as little as several weeks versus several months using this technology. The simplified construction method uses basic earthwork techniques, allowing local governments the opportunity to use their own staff in the construction of the bridge. These advantages save both time and money.

OMNNI Associates, Inc., was tasked by the county to design the two bridge replacement projects using this new construction method. Only one other bridge in Wisconsin utilizes GRS-IBS, so unique challenges were encountered during the design process.

Unique Design Challenges

Constructability

The abutments are constructed like a landscaping block wall, with alternating layers of geotextile and crushed aggregate while using modular blocks as a facing to protect the supporting layers. Site conditions, such as span length, road alignment, and geotechnical issues, dictate the layout of the GRS-IBS abutment. The bottom GRS layers are sized considering loads and ratio to wall height, and each subsequent layer is longer to integrate the roadway approach.

When Dodge County began investigating construction options, they intended to construct the bridges with their own maintenance staff and equipment. GRS abutments are well-suited for construction by municipal crews because they do not require specialized equipment or experience in bridge building. However, Dodge County has a limit on the depth of the abutment excavation by county staff, as they do not own large equipment for deep excavations or a pile driver for installing a cofferdam.

Controlling Stream Flow

The two bridges were located on small streams with similar hydraulic characteristics. Although the streams are low flow, their drainage basins are flat and rarely run dry. WisDOT requires that designers consider a two-year rain event could occur during construction. In the case of the project bridges, the two-year flow volume was about half of the 100-year event and required cofferdams to isolate the abutments from the streams.

Scour Determination

A critical consideration during the design phase is scour. Scour is the loss of streambed material caused by the flow of water. The Reinforced Soil Foundation (RSF) is a level layer of structural fill wrapped with a geotextile that supports the GRS abutments. The RSF must be lower than the expected scour depth to prevent global failure of the abutment system. It is necessary to calculate scour for a 200-year rain event. Scour countermeasures can be designed to protect against the calculated scour and reduce the depth of the RSF layer.

Soil Conditions

A subsurface soils investigation must be performed to determine if the soils at the project site can support the loads of the GRS abutments. The soils must provide acceptable bearing capacity while also resisting short- and long-term settlement. It is important that competent soils are found at relatively shallow depths to minimize the height of the wall and reduce the excavation required and corresponding cost. FHWA says the wall height should not exceed 30 feet, while WisDOT caps the height at 22 feet. For the project bridges, the depth to competent soils was 16 feet and 18 feet from the road surface.

Compressed Design Schedule

As Dodge County evaluated their options, WisDOT suggested pursuing a grant to fund the project. A typical bridge replacement project in Wisconsin has a 15- to 18-month schedule to complete various stages of design and reviews, as well as environmental documentation, utility coordination, and right-of-way acquisition. For the Dodge County projects, the grant funding required that the project be bid by construction contractors within six months after the grant was awarded. Significant coordination and cooperation between the designers, reviewers, environmental agencies, and utilities were required to meet the compressed design schedule. The grant requirement for the project to be bid eliminated the possibility of county crews building the bridges.

Construction Method

Construction began on July 5, 2016, and both roadways were open to traffic on September 17, 2016. A compressed schedule of 35 working days for the construction of both bridges was identified in the contract. As in any new process, there is a learning curve. This innovative construction method was new to the state, county, engineers, and contractors. Also, almost every material used for the construction of the bridges was an alternative to the normal method of structure construction. The learning curve and two high water events resulted in the contract taking a few days longer than anticipated. However, as the project progressed, the contractor became more efficient in their operations.

Award-Winning Design and Construction

During construction of the GRS abutments, Dodge County hosted a Project Demonstration Day in coordination with WisDOT’s Bureau of Structures to showcase the GRS-IBS technology. This learning event provided an opportunity for county highway departments, municipalities, design consultants, WisDOT staff, and construction contractors to learn about the innovative technology, its benefits, and the applications for future projects.

The project (CTH KW Bridge over Pratt Creek and CTH S Bridge over Shaw Brook) won both the state and national Project of the Year award from the American Public Works Association. In addition, the CTH KW Bridge won an Excellence in Highway Design (SW Region) from the Wisconsin Department of Transportation.▪

Link to WisDOT video and time-lapse building of the bridge: www.youtube.com/watch?v=oqSrYzrNkh8 or www.omnni.com.