The Eads Bridge was, perhaps, the best-known bridge of the 19th century after the Brooklyn Bridge. A bridge across the Mississippi River had been projected as early as 1839 when Charles Ellet Jr. (STRUCTURE, October 2006) proposed a 1,200-foot span suspension bridge. John A. Roebling (STRUCTURE, November 2006) also proposed a hybrid bridge, with a pier at mid-river, a short time later. The St. Louis and Illinois Bridge Company was formed in 1855, but nothing was done until February 1864 when the State of Missouri granted a charter. James B. Eads was named Chief Engineer on March 23, 1867, after he submitted preliminary plans in early March. By May 1867, Eads decided to build his bridge as a three-span arch bridge over the Mississippi River with the arches made of steel. To assist him, the Company named Jacob Hays Linville (STRUCTURE, July 2007) of the Pennsylvania Railroad and Keystone Bridge Company as a consulting engineer. The design was based on a bridge across the Rhine River at Koblenz (Coblenz), Prussia.

Eads first design had a central span of 515 feet and two flanking arches of 497 feet, with a minimum clearance of 50 feet above high water. He recruited Henry Flad, Charles Pfeifer, and W. Milnor Roberts as his assistant engineers. When Eads made his design known to the public in 1867, the St. Louis Democrat wrote, “What a triumph for St. Louis, the noblest river, the most glorious bridge, and the finest engineer in the world. His arch ribs were to be made of steel in the form of steel tubes in straight pieces connected together to form a polygon of 800 sides.” Upper and lower arches were to be connected by trussing, and the arches were to be fixed at the ends making them statically indeterminate. The easterly approach in Illinois consisted of a long iron viaduct with masonry arches flanking the end spans of his arches. Railroad tracks were on the lower deck, and roadways and pedestrian walkways on the upper deck.

In the meantime, Lucius Boomer was also proposing a bridge in the same area under the name of the Illinois and St. Louis Bridge Company. He had Simeon Post work out a design consisting of six wrought iron Post Trusses with two spans of 368 feet and four of 264 feet. To promote his plan, Boomer called a convention of engineers to look over all plans but with special attention to his plan. The Convention favored Boomer’s plan and recommended in their Report spans of no more than 350 feet. Eads went on the offensive and responded with “If there were no engineering precedent for 500-feet (stet) spans, can it be possible that our knowledge of the science of engineering is so limited as not to teach us whether such plans are safe and practicable? Must we admit that because a thing never has been done, it never can be, when our knowledge and judgment assure us that it is entirely practicable? This shallow reasoning would have defeated the laying of the Atlantic Cable, the spanning of the Menai Straits, the conversion of Harlem Lake into a garden, and left the terrors of the Eddystone without their warning light. The Rhine and the sea would still be alternately claiming dominion over one-half of the territory of a powerful kingdom, if this miserable argument had been suffered to prevail against men who knew, without ‘an engineering precedent,’ that the river could be controlled, and a curb put upon the ocean itself.” The two bridge companies later merged.

When Linville saw the preliminary design, he wrote, “The bridge if built upon these plans will not stand up; it will not carry its own weight… I cannot consent to imperil my reputation by appearing to encourage or approve its adoption. I deem it entirely unsafe and impracticable, as well as in fault in the qualities of durability.” Linville later, as Chief Engineer of the Keystone Bridge Company, would be in charge of building the superstructure of the bridge.

When making a case for his bridge, Eads told his investors that he could build the bridge for $3,000,000 and have it opened for traffic within 3 years. He had never built a bridge before, especially a bridge that was going to have a great deal of steel in it. Steel was used for many years, but not in bridge building or major building construction. Wrought iron by this time had generally replaced cast iron and wood in bridge construction, with much of the progress attributable to Linville and the Keystone Bridge Company plus the Phoenix Bridge Company, the Detroit Bridge Company, and others.

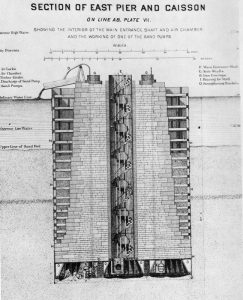

His first construction task was to place foundations for his two river piers and two abutments. Given his knowledge of the shifting sands of the Mississippi River bed, he insisted his foundations rested on bedrock and looked at various methods to accomplish this. Bedrock on the west abutment was near the surface, so it presented no problems. His east and west piers, however, would have to be sunk to depths of 95 feet and 86 feet below the river surface. His east abutment would have to reach a depth of 110 feet.

Eads learned about pneumatic caissons on a trip to Europe. Even though no one had ever used them at the depths required at St. Louis, he decided they were the only possible means to reach bedrock. While placing the foundations, 14 men were lost, mostly on the west pier, to what was to become known as caisson’s disease or the bends. By May 1870, all of the foundations were in place, and Eads could begin erecting his superstructure.

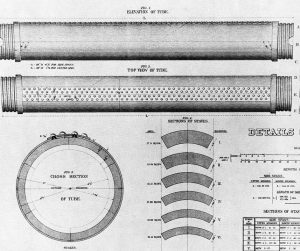

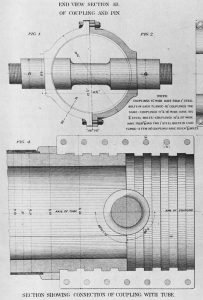

His original arches were doubled steel tubes, top and bottom, with diameters of nine inches. He later changed this to single tubes with 12-inch diameters, and even later to diameters of 18 inches. He also changed the vertical spacing between the top and bottom tubes from 8 to 12 feet, as well as having the lower arch come up tangent to the deck chords of the railroad tracks. The spans were revised to 520 feet on the center span and 502 feet on the flanking spans. Transversely, the two center arches would be 13 feet 9½ inches apart and the outer arches 15 feet 1¾ inches off the center arches.

He knew the uniqueness of his use of steel and in 1867 wrote:

“To ensure a uniform quality and high grade of steel at the lowest prices, and at the same time avail myself of the advantages of the tubular form of construction, I propose to have the steel rolled for the arches in bars of 9 feet length, and of such form that ten of them shall fill the circumference of a 9-inch lap-welded tube one-eighth inch thick, in the manner that the staves of a barrel fill the hoops. This would virtually form a steel tube 9 inches in diameter and of 6 inches bore, the steel being about 1½ inches thick, and would be much less expensive than if the tube were rolled or drawn in one piece. The manufacture of the steel in such small bars will ensure a more uniform quality in the metal, and in the tube each bar will be supported against deflection in every direction. The tubes will be retained in their positions by an effective system of bracing, which will sustain the voussoirs or pieces against which the tubes are butted throughout the arch… The tubing in which the steel bars will be enclosed will effectually protect the latter from the weather.”

His tubes were made of steel staves covered with a steel casing similar to wooden barrels. The length of staves varied, as did the thickness. Eads had to compromise his original specifications. He had significant problems in getting the quality steel he wanted for the staves as well as for the couplings that connected the tubes. Once the staves were encased, he had to mill the ends to ensure full bearing from one set of staves to the next. He also had to cut-in the threads to receive the couplings. He retained Theodore Cooper (STRUCTURE, April 2011) to handle the fabrication of the staves and couplings. Cooper was later in charge of the erection of the tubes.

Since falsework could not be placed in the river, Eads developed a way to build the superstructure by cantilever methods. He, Flad, and the Keystone Bridge Company erected wooden towers on the piers and abutments and ran links down to the arch segments to support them before the closing of the arches. He had major problems in fitting his final arch segments (the equivalent to a keystone) and had to modify them by making them adjustable.

The bridge was opened to pedestrians on May 24, 1874. The first train crossed on June 9, and it was test loaded on July 2. It was formally dedicated on July 4, 1874, with a grand celebration. Eads, in his speech, stated, in part:

“The love of praise is, I believe, common to all men, and whether it be a frailty or a virtue, I plead no exemption from its fascination. The wish to merit the good opinion of our fellow-citizens, and especially of those whom we respect and esteem, is a laudable stimulus to effort…Yon graceful forms of stone and steel, which prompt this wonderful display, stand forth, not as the result of one man’s talents, but as the crystallized thought of many, aye, very many minds, and as the enduring evidence of the toil of very many hands; therefore I would forfeit my self-respect and be unworthy of these pleasing evidences of your good will, if on this or any other occasion, I should appropriate to myself more than a humble share of the great compliment you are paying to those who created the bridge. It is of itself a high privilege to feel that I stand before you as the representative of a community of earnest men, whose combined labor, brains, and wealth, have built up this monument of usefulness for their fellowmen. For them and in their names I thank you for this magnificent evidence of your approbation…

Everything which prudence, judgment and the present state of science could suggest to me and my assistants has been carefully observed, in its design and construction. Every computation involving its safety has been made by different individuals thoroughly competent to make them, and they have been carefully revised time and again, and verified and re-examined until the possibility of error nowhere exists. When its first deep pier reached the bedrock 110 feet below the surface, those who knew nothing about the care that was used in ensuring success, expressed their gladness that my mind was relieved by the occasion. I felt no relief, however, for I knew that it must go there safely…Yesterday friends expressed to me their pleasure at the thought that my mind was relieved after testing the bridge, but I felt no relief because I had felt no anxiety on the subject. I could get no more engines or I should have imposed still greater loads upon it; for if I knew that thrice fourteen locomotives were to be put on each span and the densest crowd of humanity which was ever packed together stood upon the upper roadway above them, I should feel no anxiety whatever for the safety of the structure, for I know it is capable of bearing up vastly more than that, and I trust that those who use it hereafter will put the same implicit faith in its strength that I have. Its ability to sustain its burden depends upon laws which are as immutable as the Creator Himself, and when these laws are properly applied in estimating its strength, there need be no fear of the result…

This is a feature in its construction possessed by no other similar work in the world, and it justifies me in saying that this bridge will endure as long as it is useful to man. He, alone, will destroy it, for the earthquakes may rock its piers and shake its elastic arches in vain…

Let us not today forget these faithful toilers, no matter how humble they were, who contributed their lives in the erection of the structure, whose completion you signalize so notably…”

The bridge ended up costing $6,536,729, twice as much as Eads originally estimated. With construction starting in 1867 and opening on July 4, 1874, the bridge had taken seven years to build, also more than twice as long as Eads estimated. W. W. W. Evans stated in 1869, “Captain Eads is a bold man to design an arched bridge with spans of 500 feet and will deserve credit for his boldness and nerve if successful, but I doubt if he will deserve or receive much credit for spending two or three times the amount the circumstances called for.”

Eads resigned as Chief Engineer on July 28, 1874, and Theodore Cooper was named as his successor. After the bridge opened, it did not carry as much railroad traffic as anticipated, as the railroads needed a terminal in St. Louis and the ferry operators cut their rates for the use of rail car ferries across the river. The Bridge Company went into bankruptcy on April 19, 1875, as it could not pay the interest on its bonds. So, while an engineering success, it was a financial failure. It stands today, however, almost a century and a half after its erection still carrying traffic across the Mississippi River. It is an icon to 19th-century engineering. It was placed on the National Register of Historic Places in 1966 and was named a National Historic Civil Engineering Landmark in 1971.▪