Adding FRP Composite Sidewalks to Vehicle Bridges

“Can I walk there from here?” It’s a question more and more Americans are asking these days. A renewed focus on health and a cleaner environment are partially responsible. This new emphasis is developing into an emerging trend among Millennials, who demographers estimate to number 79.8 million, and is influencing the way developers look at city planning. Because of technologic advances, a significant percentage of the nation’s largest living generation is choosing to hang up their car keys and walk, participate in a bicycle sharing system, or hop aboard public transportation to jump start their workday.

The age group is drawn to community spaces that include walkability, proximity to public transit, and other amenities. Recent studies on the walkability of U.S. cities found that metros which prioritize pedestrian access – including San Diego, California, Cincinnati and Cleveland, Ohio, and Rochester, New York – will provide future development models for the nation’s 30 largest cities.

People are more likely to bike and walk in communities where infrastructure improvements make these activities convenient. Improvements include the installation of safer sidewalks, pedestrian crossings, and protected bike lanes. The addition of cantilever sidewalks to existing vehicle bridges is an effective option to upgrade structures that did not previously allow for pedestrian or bicycle use. Conventional materials have made this challenging for engineers working to maintain an aging infrastructure likely to have weight restrictions. FiberSPAN-C, a prefabricated Fiber Reinforced Polymer (FRP) composite sidewalk, is beginning to catch the eye of design firms looking for lightweight solutions.

While adding minimal dead load, prefabricated FRP composite sidewalks give walkers and two-wheeled travelers safe access to shared-use paths on vehicle bridges. Projects like the Wilson-Burt Bridge in Newfane, New York, are helping the emerging technology gain a foothold for acceptance by demonstrating its benefits. This Niagara County bridge was built in 1939 and designed for an H-15 live load. The 440-foot long multi-span bridge is located a ½ mile upstream from Burt Dam, a regional hydroelectric power generator, and carries Wilson-Burt Road, a primary east-west route for Newfane, across Eighteen Mile Creek.

In 1981, the New York Department of Transportation (NYSDOT) overhauled the structure’s original deck, joints, curbs, and railings. The project also included a small, concrete cantilever sidewalk on the North side. In 2011, the Niagara County Department of Public Works prepared a proposal for a rehabilitation project based on deterioration of paint, joints, the sidewalk, bearings, abutments, and piers. Greenman-Pedersen Inc., of Babylon, New York, was awarded the project.

In 2014, the closing of the Wilson-Burt Bridge began the process to ready the structure for a $4.2 million rehabilitation project geared to restore the bridge to like new condition, reopen the sidewalk (closed since 2009), and employ cost-efficient measures to preserve the structure.

“The primary concern with the bridge was its non-standard load capacity,” says Brian Carlson, a senior structural engineer for Greenman-Pedersen and project manager for the Wilson-Burt Bridge project. “The bridge was designed for an H-15 live load. Today we design for HS-25 or HL-93 live loads, depending on criteria.”

Upgrading bridge capacity and re-opening its sidewalk were key goals for the county, along with addressing the deterioration of the existing piers. With urban services available to the south, coupled with industry and recreational opportunities provided by Lake Ontario to the north, proximity to an urban economy has boosted Newfane’s growth. Wilson-Burt Bridge is the largest bridge crossing owned by Niagara County and is an important farm-to-market road for the local economy.

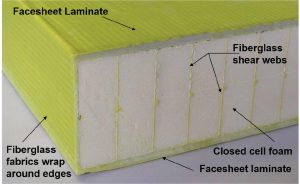

Figure 1. FRP sandwich construction uses redundant fiberglass shear webs to connect top and bottom face sheets for maximum bending properties and reduced weight.

“We wanted to restore the sidewalk, but it had to be lightweight so that it did not impact the vehicular load-carrying capacity of the bridge,” says Carlson. “We researched a variety of sidewalk systems including concrete, steel grids, and timber. We narrowed our selection to Composite Advantage’s FiberSPAN composite product. The sidewalk’s sandwich construction (fiberglass facing skins on fiberglass webs in foam core) and design flexibility demonstrated it was the best choice” (Figure 1).

Carlson says he contacted Composite Advantage about the project and received comprehensive details on panel construction, materials, and installation protocol, information he used to include FiberSPAN in design plans for Wilson-Burt. Greenman-Pedersen then prepared a unique specification for the FRP sidewalk and gained approval from the NYSDOT.

Figure 2. New gray W-8 I-beams bolted on top of the original green W-40 beams demonstrate the lightweight FRP product’s design flexibility to increase clear sidewalk width and support modern traffic requirements.

The existing sidewalk needed to be widened to 5 feet, 5¼ inches (Figure 2) to support modern traffic requirements. The project specified an allowable live load of 85 psf for the FRP sidewalk, with deflection limits of L/500 between supports and an uplift load of 30 psf. The sidewalk was designed to withstand a temperature differential of 100°F. Floor beam spacing was set at 10 feet, 10 inches, with a deck cross slope top surface of 1.76 percent for efficient water drainage (Figure 3).

Fabricating panels with a cross slope is easier and more cost-efficient than sloping support beams or installing shims. The 22-foot long FRP panels were prefabricated with a shop applied non-slip surface and internal steel connection points to accommodate attaching the railing directly to the sidewalk panels (Figure 4).

“In addition to increasing sidewalk width, the lightweight characteristics of FRP allowed the material to maintain a dead load that was less than the sidewalk’s original weight,” notes Carlson. For a 440-foot length bridge span, dead load for the FRP sidewalk was 69,690 pounds. Live and dead load totaled 275,380 pounds. A concrete deck on steel pan and supports would have added an extra 180,000 pounds to the sidewalk’s dead load.

Following an open bidding process, the job was awarded to heavy highway and site contractor EdBauer Construction, West Seneca, New York.

“We had never used FRP before,” says Bill Bauer, president of EdBauer Construction. “But we decided to go with it for several reasons. Composite Advantage performed a significant portion of the engineering layout and design work for the panels, as well as providing detailed installation procedures. They had their design calculations and drawings verified and signed by an engineer registered in New York. After we removed the existing concrete grid deck and exposed the structural steel, they also came out and performed field measurements in order to fabricate the decking to fit conditions.”

Sidewalk installation was slated to follow restoration and replacement activities on the vehicle bridge. Work included complete removal and reconstruction of the upper portion of the span’s three piers, as well as the upper portion of abutment back walls. Other tasks included lead paint removal and the addition of a new 8-inch waterline for residents. The construction crew suspended a corrugated platform underneath the structure to give workers access to the structural steel.

Bridge joints and deteriorated structural steel cross-frames adjacent to the piers were replaced. High rocker bearings were switched out for seismic isolation bearings on new pedestals. EdBauer engaged BIDCO Marine Group based in Buffalo, New York, to perform underwater concrete repairs to the piers while they took to Eighteen Mile Creek on barges to tackle pier repairs above the waterline. After attaching a structural framework to the pier, workers had to jack up the bridge and remove the pier cap to accommodate concrete repairs and reinstall rebar. The labor-intensive process was repeated for each of the bridge’s three piers.

“Access issues are always on the top of our list of concerns when you are working over water,” says Bauer. Temperature and weather conditions were also worrisome. “We felt a bit apprehensive about the FRP sidewalk,” he continues. “We were working late in the season. Cold temperatures made working conditions less than ideal. With conventional material, rain and cold weather would have presented a problem. We would have had to heat the concrete or structural steel to install the sidewalk. But the FRP panels went in quickly. We had the deck put on in a week. And because they were laid out correctly, the installation went flawlessly” (Figure 5).

FRP panels arrived at the job site on a flatbed truck to make installation easy. The construction crew was able to unload the panels one at a time to create two stacks of 10 that could be installed from the top down, working west to east.

“We did not have to weld structural steel or pour concrete,” continued Bauer. “We only needed a small piece of equipment to move the panels. Because the bridge had been rehabilitated once before, some of the structural steel was not uniform, but the advantage provided by the product’s flexibility allowed Composite Advantage to come out and make some adjustments before our final inspection.” (Figure 5)

Technical coordination and upfront prefabrication eliminated the potential for major fit rework on-site. Installation and deck connections allow for fit-up tolerances on the bridge to accommodate lack of uniformity.

Niagara County, NYSDOT, and Greenman-Pedersen conducted a walk-through inspection after Wilson-Burt Bridge re-opened in November 2015 and found the FRP sidewalk installed according to specification. Subsequent biennial bridge inspections have found the FRP sidewalk performing to specification.

“Now that we have some background in FRP, I’d love to work with the material again,” says Bauer. “The coordinated effort of Niagara County, Greenman-Pedersen, and Composite Advantage minimized any on-site issues. The project was on time and budget.”

FRP material selection helped Greenman-Pedersen overcome the unique challenges presented by restricted loading conditions, the inability of the work site to accommodate large equipment, and the need for traffic closures to be kept to a minimum. In addition to FRP’s lightweight and quick installation, a non-slip aggregate surface supports pedestrian safety. The material’s zero maintenance characteristic also demonstrates its potential for use in similar projects for urban settings. ▪