The Williamsburg Bridge across the East River in New York City is now over 100 years old. After a complete rehabilitation, it is still considered by some the “Ugly Duckling” of suspension bridges. In May 1883, the Brooklyn Bridge opened over the East River between New York City and Brooklyn. Even before the Brooklyn Bridge opened, however, residents of Williamsburg created an organization to pressure politicians for a new bridge. No real action resulted from this pressure. It was into this period of inaction that Frederick Uhlman and his associates from the Brooklyn Elevated Railway moved in early 1892. They put together a strong base of support in the legislature. On March 9, 1892, the East River Bridge Company, a private corporation, received a charter from the State of New York to build two bridges to form a loop transit line connecting Brooklyn and Manhattan.

After the passage of the bill, the company retained George B. Cornell in April 1892 as its chief engineer. He planned a suspension bridge, similar to the Brooklyn Bridge, with a span of 1,620 feet and a width of 106 feet to accommodate four tracks for passenger trains, two driveways, and a promenade. The towers would be 280 feet high with a clearance over high water of 135 feet, the same as required for the Brooklyn Bridge. Cornell proposed that the towers be made of masonry to a height of 180 feet above the water level and that the remaining 100 feet be made of steel.

The company submitted plans for both bridges to the Board of Alderman of Brooklyn in early October, and they approved the plans on November 22, 1892. The company also went before a Board of Engineers representing the Secretary of War for approval. To the surprise of many, the Board recommended a clearance of 145 feet to the Secretary of War. The company appealed this recommendation and requested a hearing with the Secretary of War. In mid-January, 1893, the Secretary approved a clearance of 140 feet, but little work was done for over a year.

Based on the slow progress made by Uhlman, Brooklyn Mayor Charles Schieren pushed for a bridge owned by the two Cities. He told the New York Times, “We propose to build a bridge similar to the Brooklyn Bridge, and one that will be a thing of beauty and a joy forever. I have not consulted Manhattan Mayor Strong yet in regard to the matter, but I think he will acquiesce in anything that is for the benefit of the two cities.” Mayor William L. Strong went along and together they presented their proposal to the Legislature, who approved it on May 27, 1895.

Commissioners were appointed and met with the Mayors of both cities for the first time on June 26, 1895. Their first problem was selecting a Chief Engineer. From the multitude of engineers available, eleven applied including Leffert L. Buck, Virgil Bogue, George Morison, William Burr, A. P. Boller and others. The choice evidently came down quickly to Leffert L. Buck, George Morison, and Virgil Bogue. Buck (STRUCTURE magazine, December 2010) was selected to design what was to be the longest and most heavily loaded suspension bridge in the world. His decision was to concentrate on one bridge, not the two bridges originally chartered.

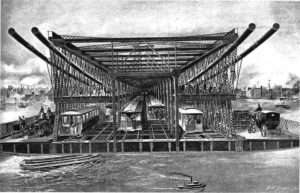

On August 7, the commissioners and Buck met with Uhlman and Cornell to discuss the bridge. Uhlman indicated he did not see how the engineers of the Commission could plan a bridge that would not interfere with his company’s rights. For the rights of his company, he wanted $200,000 which he eventually got. On January 23, 1896, Buck submitted his report recommending a six-track layout, based on the original plans for four tracks, two roadways, and a promenade. He decided “the best arrangement seems to be to place the elevated tracks in the middle, and to have two trolley tracks on each side of them.” The commissioners, after much discussion, unanimously resolved to “construct a bridge, not exceeding 118 feet in width, with six tracks thereon, two for elevated railroad service and four for the surface railroad service, with all the necessary approaches and switches, and terminals – all tracks to be on the same level at the centre of said bridge, and to build a promenade for pedestrians over said tracks.” O. F. Nichols, Buck’s Rensselaer classmate, was appointed Buck’s first assistant engineer. On February 6, 1896, an engraving of Buck’s bridge was printed in the New York Times. The article said that the main span would be 1,700 feet and it would be the “Stiffest Suspension Span in the World and the Longest.” The “estimated cost of the bridge is $12,000,000 – $8,000,000 for the bridge proper and $4,000,000 for the approaches.”

Buck and the commissioners went back to the War Department to obtain approval for the 135-foot clearance granted the Brooklyn Bridge, which was finally given on February 28. Buck concluded that a 1,600-foot “continuous stiffened suspended structure” was the best and added, “There is no more durable bridge than a well-built suspension bridge, and said there is no more enduring reputation than that of the man who will sometime in the future build one of large size as it should be built.” He described his bridge as follows:

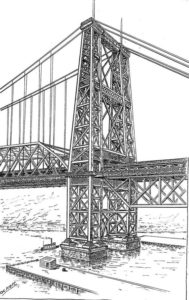

The towers are of steel columns thoroughly braced, eight columns to the tower on each side of the river. The distribution of the roadways and tracks were to be passed through the tower, the tracks in the middle portions or openings and the roadways to pass through between the columns on that side of the tower. This fixed the width of the tower at the roadway. The cradling of cables before mentioned and position of the trusses fixed the position of the columns at the top of the towers, as it was desirable to have each pair of columns rest directly under the saddles in which the cables were to rest. This arrangement gave considerable batter to the tower above the roadway in a transverse direction. In the longitudinal direction, the tower at the roadway had a width of 40 feet longitudinally, and at the top of the tower about a width of 20 feet was required; and the saddles are 19 feet long and between centers of the columns at the top longitudinally there is a distance of 15 feet, making a batter in that direction…

On July 22, 1896, the plans were approved. The caissons were to be sunk by the pneumatic method. On top of the caisson, the masonry would be placed. Unlike the Brooklyn Bridge, the masonry only extended a short distance above the river level. The anchorages were to be approximately 150 feet by 180 feet in plan and 75 feet high.

In May 1897, the commissioners approved a slightly revised plan. At that time, Buck estimated that he could build the bridge for $7,510,000 and, “if all the contracts for the bridge are completed” in accordance with his schedule, would open on January 1, 1900. Contracts for the foundation, caissons, and stonework of the two towers and the two anchorages were let in 1897 for a sum of over $2.4 million dollars. Work on the tower foundations began in the late summer and early fall of 1897. They were completed in September 1898. Work on the anchorages also started in late 1897, with the Manhattan anchorage completed in June 1898 and the Brooklyn anchorage completed in December 1899.

In 1898, in a general election, the Greater New York Act was passed that merged the cities of New York, Brooklyn, Queens, the East Bronx, and Staten Island. The commissioners and Buck were of the opinion that this change in governmental structure would have no impact on the construction of the bridge. They were wrong. The new Mayor, Robert A. VanWyck, relieved the commissioners and replaced them with an entirely new set of commissioners on January 20, 1898. The New York Times reported, “Engineer Buck, who was an engineer for the old commission, will probably be retained. President Nixon said that the new commission had every confidence in Mr. Buck and that there was no reason for a change.” The cities did not always make sufficient funding available but, in spite of this and other delays, the tower piers and anchorages went on without much delay.

The contract to spin the 18½-inch diameter cables and attach all the suspenders was awarded to John A. Roebling Son’s Company on January 1, 1900, for the sum of $1,398,000. Buck made many changes to what Washington Roebling used at the Brooklyn Bridge on his cables and suspenders. Instead of galvanizing the wires, he took other steps to minimize corrosion. His first step was to have the wire soaked in hot linseed oil at the mill. After the wire was spun into a strand consisting of 281 wires and banded, he had all the voids filled with what he called a “special anti-oxidation filling.” When the strands were all banded into a single cable, he had the voids filled with the same material. The next step was to attach the suspender castings tightly to the cables every 20 feet. Instead of wrapping the cables with wire as Roebling had done, Buck decided to encase the wire in a 1/16-inch thick steel jacket overlapped to prevent the penetration of water.

Contracts were let for the steel towers to the New Jersey Steel and Iron Company on February 21, 1899, in the amount of $1,220,230. The Pennsylvania Steel Company won the contract for the suspended steel structure and both approaches at a price of $1,123,400. The project was primarily a Rensselaer Polytechnic Institute project with Buck and Nichols as engineers, and John A. Roebling & Sons with Washington Roebling still active in the company along with his son who was also a Rensselaer graduate. John V. W. Reynders from the Pennsylvania Steel Company was also a Rensselaer man.

The deck structure was much heavier than that at the Brooklyn Bridge. The four cables were placed at the ends of long, deep plate girders. The cables started 34 feet apart at the end of the anchorage, converging to 22 feet apart on top of the towers. From there they converged to 4 feet apart at mid span. Wire spinning would not begin until November 27, 1901. Once commenced, however, the cable spinning was carried to completion in only seven months, the last wire laid on June 27, 1902.

Once again things were going well for Buck and the bridge when, on January 1, 1902, Seth Low became Mayor of New York. He, in turn, appointed Gustav Lindenthal as Bridge Commissioner with full authority for the bridges planned and under construction in the city.

One of Lindenthal’s first actions was to reorganize “his office by appointing Mr. L. L. Buck as chief engineer of the entire department, with Mr. R. S. Buck as a principal assistant engineer and chief engineer of the East River Bridges No. 3 and 4 (Blackwell’s Island and Manhattan Bridges)…Mr. O. F. Nichols remains in charge of the New East River Bridge with the rank of principal assistant engineer…” It became immediately clear that Lindenthal and the Buck group did not see eye to eye on the design of large bridges, particularly the East River Bridge. R. S. Buck resigned on May 1, 1902. Leffert Buck, with the support of many New York Engineers, vocally and in the press, challenged Lindenthal, who threatened to fire him. On May 3, 1902, Mayor Low, to clarify responsibilities and resolve the fighting, issued the following notice: “The Bridge Commissioner has appointed Mr. Leffert L. Buck consulting engineer of the Williamsburg Bridge, at a salary of $7,500. This is in accordance with an understanding mutually agreed upon in consultation with the Mayor and Mr. Buck. The intention is to assure to Mr. Buck the same relation to this bridge, as its engineer, which he has occupied from the beginning.” Other than a reduction in salary of $2,500, Buck was still in charge of the bridge with Nichols as his assistant. O. F. Nichols was fired by Lindenthal on July 1 for his statements against Lindenthal’s change in the design of the Manhattan Bridge.

One of the few problems of this period occurred on November 10, 1902, when a worker’s shanty on top of the Manhattan tower caught fire. Lindenthal appointed a commission consisting of L. L. Buck, George Morison, and C. C. Schneider to report “as to the extent and manner in which repairs shall be made to the steel wire cables and the other steelwork…” After testing the wires, they determined the strength of the outside cable had been reduced by only 2.5%. Since the wire as furnished was 12% stronger than specified, they determined that the cables were still stronger than needed.

Bridge Opening

The opening of the bridge on December 19, 1903, was a great success featuring a large parade in the afternoon. The New York Times wrote, “NEW BRIDGE IN A GLORY OF FIRE; Wind-Up of Opening Ceremonies a Brilliant Scene. BIG FLEET IN PARADE – Daylight Dedication Ceremonies and Night Spectacle Witnessed by Immense Crowds – Enthusiasm on Both Sides of the River.”

Buck would not ride with Lindenthal near the head of the parade and instead rode in his own carriage with his wife. When he got to the spot where the ceremonies were to be held, he and O. F. Nichols took a seat well away from the speaker’s stand. It was now time for Mayor Low to accept the bridge, but to whom would he give credit for the design, Buck, Lindenthal, Nichols or would he simply not mention the designers at all? To the surprise of many, Low was very complementary to Buck, mentioning his Civil War Experience and more. This tribute to Buck surpassed that given to most bridge engineers at or since that time.

The foot walks opened later, on April 24, 1904. It was estimated that over 25,000 people crossed between 10:00 am and 3:00 pm on that date. The first cars of the Metropolitan system crossed the bridge on the last day of 1904. Riding on that first car were many engineers and dignitaries, including “Chief Engineer and Mrs. Lefferts Buck.” The Bridge was named a National Historic Civil Engineering Landmark in 2009 and remained the longest span suspension bridge in the world for 21 years, until the Bear Mountain Bridge across the Hudson River opened in 1924 with a span of 1,631 feet.▪