Lighter, shallower, and cheaper: composite steel joist floor systems can save costs, save materials, and optimize space. These cost-saving reasons for designing a composite steel joist floor system are described in depth along with how these proven systems are best coordinated between the specifier and the joist manufacturer.

Lighter Materials Reduce Costs

When joists are supporting a concrete slab, the specification of composite joists – as opposed to standard Steel Joist Institute (SJI) non-composite joists – should be investigated, because they are lighter. Potential weight savings can be determined by using the project-specific design loads in conjunction with Load Resistance Factor Design (LRFD), composite steel joist weight tables, and the joist manufacturer’s economic joist design table. Used in floor construction applications, composite joists improve the efficiency and advantages of non-composite joists. For example, accounting for the concrete slab adds extra strength, allowing the joist top chord to be smaller and therefore, reducing material, because the joist alone does not support full design loads.

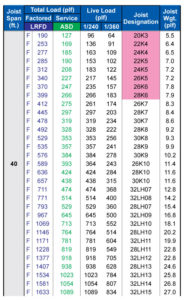

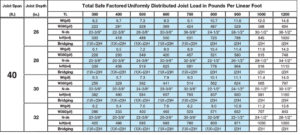

Composite joists are typically designed using the LRFD design method to be consistent with the concrete slab design. For example, consider a joist spanning 40 feet, spaced at 4 feet on center, subject to 25-psf non-composite/construction dead load, 50-psf composite superimposed dead load and 100-psf composite live load. Using the appropriate LRFD factors, the total load to be carried by the joist is 1000 plf. A non-composite joist design shows a 32LH10 is the most economical at 18.1-plf joist weight. Conversely, a composite joist design shows the same 32-inch deep joist would weigh only 11.2 plf, which is a 38% savings in the material per joist (Figure 1).

Shear Studs Are Key Difference

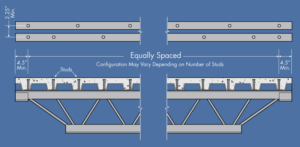

Composite joists are manufactured open-web steel trusses used to support floors and roofs with a structural concrete slab. The main difference between composite and non-composite joists is that shear studs are attached through the composite steel deck to the joist top chord (Figure 3). A composite section is created between the slab and the joist top chord after the concrete is poured and cured. This composite action allows for the use of a lighter joist. The reduction in weight is due to designing the joist to withstand only construction loading with no strength contribution from the slab and then designing the joist top chord as a composite section with the slab to withstand the full-design loading after the concrete has cured. Conversely, non-composite joists are designed to support the full design loading, assuming there is no strength contribution from the concrete slab because there are no shear studs present. Using this design methodology allows for composite joists to build on the efficiency and benefits inherent in using open-web steel joist construction.

Optimize Space Using Shallower Floors

Using a composite joist narrows the floor, creating more headroom, often with adequate MEP routing options through the joist. Also, shear studs increase joist strength, thereby expanding the span-to-depth ratio limit to 30 times the joist depth, compared to 24 times the joist depth for non-composite joists. The increase in headroom can be achieved with no loss in the length of the joist span. For example, a non-composite 24-inch deep joist can span up to 48 feet; however, a 20-inch deep composite joist can also span 48 feet. The shallower composite joist floor may still accommodate MEP integration. If larger duct penetrations are required, contact the joist manufacturer to determine the feasibility and options available for special web layouts to accommodate duct penetrations. For the same example above, if the building design required limiting the joist depth to 28-inch deep, a non-composite joist would weigh approximately 20.2 plf, while a composite joist would weigh approximately 11.6 plf. Therefore, using a composite design in this situation would allow for an additional 4 inches more of headroom and would only slightly increase the joist weight as compared to a non-composite design.

Reduce Steel and Related Costs

Another composite joist benefit is the ability to space joists farther apart than non-composite joist framing. Fewer joists can often translate to reductions in steel cost, manufacturing cost, shipping costs, and erection costs. Joists in a floor application are generally spaced at 2 feet on center. It is not uncommon for composite joists to be spaced 4 or 5 feet on center and beyond. Minimum chord width and thickness requirements must be met depending on shear stud diameter. That said, the objective is to space joists farther apart than typical floor joist framing to assure the joist top chord is fully utilized for maximum cost savings. Any cost savings expected by using composite joists is lost if they are spaced too close together.

Responsibilities of the Specifying Professional

Understanding what is expected of the specifying professional and the joist manufacturer when electing to use a composite joist system guarantees a smooth project life cycle. Not only will this minimize questions during the approval process, but complete design information allows the joist manufacturer to provide an accurate price during the quoting phase. Most importantly, clear communication reduces the likelihood of change orders due to missing information during the drawing approval process.

All Design Loading

The construction requirements between the specifier and the joist manufacturer are similar to those on a conventional joist project. However, due to the special nature of composite joists, additional information is required as outlined in the SJI Code of Standard Practice for Composite Steel Joists. A breakdown of all loading to be considered in the joist design is critical information for the joist manufacturer. Since the joist is designed for two different loading situations – during construction and after construction – a breakdown of the dead and live loading for each phase is required.

The loading that the joist is subjected to consists of the non-composite construction dead load and the construction live load. Each of these non-composite loads should include any loading the joist is expected to carry prior to the concrete slab curing. This includes, but is not limited to, the joist self-weight, the wet-concrete weight, and any equipment and personnel loads expected during the pouring of the slab. The second phase of loading required is the composite dead load and composite live load. These loads would typically include the building code prescribed live loads and the total of the non-composite dead load plus any expected superimposed dead loads not accounted for in the construction phase. Additionally, if there are to be any considerations for concentrated loads, axial loads, or end moments, these must be shown in the drawings, in the notes, or on a load diagram. Explicitly displaying this loading information on the structural plans facilitates accurate and economical joist design.

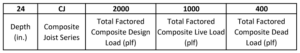

Knowing the best way to represent composite joist design criteria on structural drawings is just as important as knowing what information must be provided. The most direct way to convey design criteria is to display it all in one table including slab, deck, and joist design requirements. Also, showing joist designations on the plan, in the form required for composite joists, avoids confusion for the joist manufacturer. The SJI format for a composite joist designation is 24CJ2000/1000/400. See Figure 2 for the definition of joist designation.

It is permissible to supply service loads for Allowable Stress Design (ASD) joist design. However, it must be clearly indicated on the drawings that service level loads are provided in place of factored LRFD loads. In the SJI Code of Standard Practice for Composite Steel Joists, there is a composite joist design parameter checklist to assist specifying professionals in identifying information required by the joist manufacturer. Using this checklist as a guide and representing this information on structural drawings ensures that the joist manufacturer has the design criteria necessary to quote and design a composite joist framing system.

Manage Camber and Vibration Challenges

Camber specification is often overlooked on composite joists. SJI recommends the joist be cambered for a minimum of 100% of the non-composite dead load. The inclusion of a camber results in the joist being flat after the concrete slab has cured. If a flat joist under a different loading condition is desired, the joist manufacturer must be advised on which loading to use in determining joist camber. For example, a joist is cambered for 100% non-composite dead load + 50% composite dead load + 10% composite live load. Although the camber is a function of many variables, it is typically in line with the SJI standard camber published in the SJI catalog.

Vibration analysis is also an important design factor when using composite joists in a floor application. The specifying professional is responsible for conducting the required vibration design analysis of the floor system to verify the floor framing meets the project requirements. See the sidebar for additional resources on joist vibration.

For more information on vibration considerations, contact the joist manufacturer. They are able to provide direction on conducting vibration analysis. However, final confirmation of the framing adequacy is the responsibility of the specifying professional.

Responsibilities of the Joist Manufacturer

Similar to a conventional project, the joist manufacturer provides joist placement plans containing all relevant information required for erection. Due to the nature of composite joist design, all design criteria is represented on the joist plans. This includes, but is not limited to, the design loading, camber, shear stud information, and slab information provided by the specifying professional. Shear stud criteria includes the diameter, quantity, and a simple shear stud layout (Figure 3). Shear stud sizes vary from 3/8-inch ø to ¾-inch ø. All of this information is typically provided in tables displaying the total quantity of studs required for each joist. Note, shear studs are not furnished by the joist manufacturer.

In Conclusion: Communicate

Providing clear expectations and open lines of communication between the specifying professional and the joist manufacturer leads to a seamless design process, from beginning to end. Additionally, there are significant cost savings due to the three benefits of using composite joists: materials reduction, shallower structural floor framing, and the savings realized in the erection phase. Consider composite steel joists when designing your next floor system to improve floor strength and reduce costs.▪

Steel Joist Institute (SJI) Additional Information

- The SJI Standard Specifications for Composite Steel Joists provides guidance on allowable duct sizes based on joist depth.

- Also available through SJI are design tools to assist in floor vibration analysis. Visit for more information on available design tools.

- SJI provides direction on conducting vibration analysis of floor systems in Technical Digest number 5.

- Introduced by the SJI in 2007, composite steel joists or CJ-Series joists take the efficiency of steel joists and improve upon it by accounting for the composite action between the concrete slab and joist top chord.