Many buildings and other structures include structural components that are parts of suspended scaffold and rope descent systems used to gain physical access to elevated areas. The Occupational Safety and Health Administration (OSHA) federal regulations include many provisions related to the design and evaluation of suspended scaffold systems and related items such as equipment tieback and lifeline support anchorages. While many of the relevant OSHA provisions are clear and consistent, several important structural requirements are either unclear, inconsistent with one another, or both. However, the International Building Code (IBC) is very clear on the structural requirements for the design and load testing of façade access support equipment (FASE). The different types of FASE consist of davit and davit bases (Figure 1) and fall arrest anchors (Figure 2). The purpose of the FASE is to support the suspended system, including powered platforms (Figure 3), rope descent systems (RDS) (Figure 4), and lifelines. This article provides specific commentary concerning the OSHA and IBC structural provisions regarding FASE design and load testing and presents proper approaches to load testing of FASE.

…Review Category : Structural Practices

To Top Rail or not to Top Rail

The engineering of guardrails has generally been straightforward ever since they were first addressed in building codes. Even the earliest building codes, like the Uniform Building Code (UBC) and the Building Officials and Code Administrators’ (BOCA) National Building Code, had live load requirements for typical handrail and guardrail scenarios.

…Ways to Ensure Deployed Flood Barriers Work

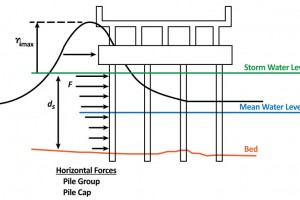

Imagine spending millions of dollars on flood protection but, when a storm approaches, the deployable flood barriers cannot be installed in time. Learning from experience and adding some common sense helps reduce the risk of improperly deploying flood barriers. Storage, maintenance, and deployment execution are the primary considerations for barrier selection and must be vetted fully during preliminary and final design to reduce operational challenges. Labeling and storing components in a readily accessible position and having deployment plans that are well thought out promote the flood mitigation system’s overall success. Deployment-related risks can be decreased by minimizing the number of components assembled in the field.

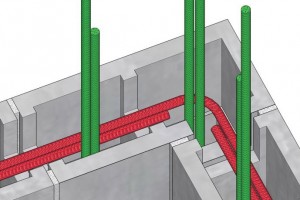

…Structural engineering education includes fundamental principles of mechanics of materials and structural analysis that help engineers to understand and design structural members and systems. Occasionally, it is necessary to wander into design considerations outside of the structural realm, such as corrosion protection and serviceability. Still, rarely are structural engineers taught to prioritize constructability as a primary focus of structural design. This consideration often comes with experience as it is learned that the most efficient or elegant structural solution is not always the easiest to construct or (arguably more important) the least expensive. Structural engineers’ limited education on masonry materials and limited exposure to masonry construction processes can magnify installation issues. This article highlights how engineers can avoid some of the most common constructability issues with modern structural masonry.

…Design and Construction Considerations

Existing owners often consider repositioning options for their buildings to serve an ever-evolving tenant market, accommodate new building uses, improve pedestrian circulation and accessibility, increase rentable tenant space, and more. Often, these buildings are served by an abutting above-grade parking structure, which can prevent horizontal expansion unless portions of the garage are removed to accommodate the expansion. …