A 120-year service life is achievable in buried galvanized structures. Hot-dip galvanizing (HDG) is the process of immersing fabricated steel or iron into a kettle (bath) of molten zinc. While in the kettle, iron in the steel metallurgically reacts with the zinc to form a tightly-bonded alloy coating. Hot-dip galvanizing resists corrosion by providing barrier and cathodic protection, as well as through the development of the zinc patina. These three levels of corrosion protection provide galvanized steel with maintenance-free longevity for decades. …

Review Category : Building Blocks

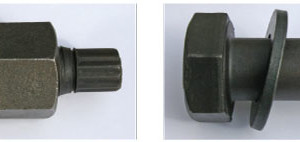

Several significant changes have or will soon occur in high-strength bolting for steel buildings. These changes have been incorporated into the latest drafts of the upcoming AISC Specification for Structural Steel Buildings (AISC 360-16), and related AISC standards such as AISC 341 and AISC 358. The Research Council on Structural Connections (RCSC) is beginning work on a new version of the Specification for Structural Joints using High-Strength Bolts to address these changes. AASHTO bridge design and construction specifications are also in the process of addressing these changes. …

Fundamentals of Hardened Concrete

Monolithic concrete with a compressive strength in excess of 3500 pounds per square inch (psi) is watertight, except at any irregularities in the structural element. Typical locations where irregularities occur include overhead decks, floors, and walls that have cracks, honeycombs, joints, mechanical/electrical penetrations, and form-tie supports. …

Fiber-reinforced polymer (FRP) composites have been used for structural strengthening in the United States for almost 25 years. During this period, acceptance of FRP composites as a mainstream construction material has grown, and so has the number of completed FRP strengthening projects. As a result, the use of FRP for strengthening and retrofit is gaining more popularity among design professionals over conventional strengthening techniques, such as installation of supplemental structural steel frames and elements. …

Designers dedicated to restoring ecosystems and enhancing social conditions through the built environment know that wood can contribute significantly to this aspiration. Although timber used as structural elements in taller buildings is not a new concept, it has been largely abandoned as a solution in favor of other materials. Projects around the world are demonstrating the potential of engineered, mass timber products as structural elements for tall buildings, and wood is re-emerging as a viable and beneficial option. …

What Is It and Why Would I Use It

Despite the fact that cellular concrete has been used in the construction industry for nearly a century, it is not uncommon for designers to be unfamiliar with this versatile lightweight product. “What is this stuff?” and “Why haven’t I heard of this before?” are very common questions. …

Advanced Steel Curtain Walls Provide Enduring Beauty

When San Francisco’s Hallidie Building opened in 1918, its seven-story glass and steel skin launched the era of glass curtain walls. Using the strength of reinforced concrete and structural steel, the building team suspended the glass panes in a steel framing grid to create the illusion of a floating wall. …

Wood frame construction utilizing traditional and engineered wood products is the predominant method of building homes and apartments in the United States. Increasingly, wood framing is also being used in commercial and industrial buildings due to its economy and architectural flexibility. Wood frame buildings are economical to build in a wide range of climate zones. …

New Technologies Push Strengths to New Heights

As recently as 25 to 30 years ago, the steadily increasing availability of concrete with compressive strengths above 6,000 psi had the industry’s rapt attention. Back then, in many regions, strengths this high were considered revolutionary. Some people even questioned the need. …

Until the middle of the 19th Century, wood was commonly used as a primary structural building material in many types of non-residential buildings around the world. Many of these timber-built structures remain standing and are still in use today, including factories, warehouses, schools, temples, and churches – some dating as far back as the seventh century. …